DST support nurtures technologies to smarten agricultural processes

DST has developed a host of affordable and easy to handle technologies that can cut short lengthy agricultural processes like sowing of seeds, drying of biomass and growth monitoring.

These include a low cost technology that can indicate and hence help eliminate choking of seed drill (an tractor driven implement for the purpose of sowing seeds), computer operated portable device for appearance based quality analysis of multiple crop, hot air generation system integrated with solar tunnel dryer to help quicker drying of biomass, Aloevera gel extraction equipment, wireless embedded systems for monitoring the environment of ware house and green house.

The affordable technologies developed by the Technology Development and Transfer (TDT) division under Department of Science & Technology (DST) can go a long way in integrating innovative solutions to reduce cumbersome agricultural processes, help enhancement of productivity and doubling farmer income.

An improved seed drill choke indicator for tractor driven seed drill

The seed cum fertilizer drill is a tractor driven implement for the purpose of sowing seeds and application of fertilizers in the field. It drops the seed and fertilizers at specified rate with pre-set arrangement for placement. The main problem with most of the presently available seed cum fertilizer drills are that they get intermittent obstruction in sowing and fertilizer applications due to the blockage of channels. This causes non-uniform distribution and also reduces the yield. The above problem is more serious when sowing is done during night times.

The seed cum fertilizer drill is a tractor driven implement for the purpose of sowing seeds and application of fertilizers in the field. It drops the seed and fertilizers at specified rate with pre-set arrangement for placement. The main problem with most of the presently available seed cum fertilizer drills are that they get intermittent obstruction in sowing and fertilizer applications due to the blockage of channels. This causes non-uniform distribution and also reduces the yield. The above problem is more serious when sowing is done during night times.

The innovated device which is ready for commercialization eliminates the above said problems by online monitoring of seeding activity and removal of choking channels whenever it occurs. The improved seed cum fertilizer drill choke indicator will be an attachment to the seed cum fertilizer drill available in the market. This innovation enhances the accuracy of seeding and fertilizer placement of the classical seed cum fertilizer drill.

The technology is low cost and affordable for farmers. Besides, any parallel device is not available in India. The closest solution is a precision seed drill which is is costly and not manufactured in India.

IP Ownership: Jawaharlal Nehru Krishi Vishwa Vidyalaya, Jabalpur

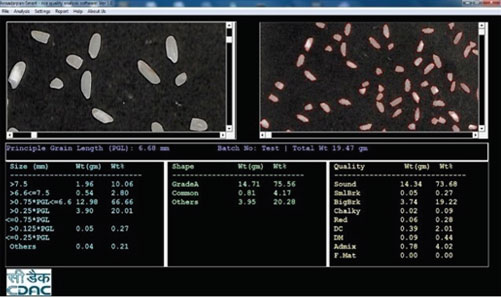

Annandarpan Smart - A machine vision software for multi-crops analysis

ANNADARPAN SMART is a computer operated, portable device for appearance based quality analysis of multiple crops such as Rice, Paddy, Tur, Wheat, Bengal gram, Moong, Barley, Soybean etc. Image analysis solution for rapid objective assessment of crop quality has been developed by capturing and analyzing images using a scanning device. The imaging device is interfaced with a computer using a universal serial bus (USB). Sample is required to be spread manually on a sample handling tray which is placed under the imaging device kept inside an enclosed chamber. Crop specific, separate software has been developed for appearance based quality analysis.

ANNADARPAN SMART is a computer operated, portable device for appearance based quality analysis of multiple crops such as Rice, Paddy, Tur, Wheat, Bengal gram, Moong, Barley, Soybean etc. Image analysis solution for rapid objective assessment of crop quality has been developed by capturing and analyzing images using a scanning device. The imaging device is interfaced with a computer using a universal serial bus (USB). Sample is required to be spread manually on a sample handling tray which is placed under the imaging device kept inside an enclosed chamber. Crop specific, separate software has been developed for appearance based quality analysis.

This new technology for which a prototype has been developed allows large sample handling in single operation and has a wide range of quality analysis like Good, Immature/Broken, Admixture, Chalky grains, Red grains, Damaged/Discoloured grains.

Besides, it also allows the following unique facilities:

- Foreign matter detection for rice and other pulses.

- Uniform illumination with built in light arrangement.

- Faster image aquisition and analysis.

- High resolution image capture for accurate image analysis.

- Portable system solution for easy field-operability

IP Ownership: Centre for Development of Advanced Computing (C-DAC), Kolkata

Biomass Hot Air Generation system integrated with solar tunnel dryer (Hybrid biomass-solar dryer with auto-controller)

The Biomass Hot Air Generation system integrated with solar tunnel dryer (Hybrid biomass-solar dryer with auto-controller) which is ready for commercialization integrates two sources of heat to facilitate quicker drying of biomass, a cumbersome agricultural process.

The Biomass Hot Air Generation system integrated with solar tunnel dryer (Hybrid biomass-solar dryer with auto-controller) which is ready for commercialization integrates two sources of heat to facilitate quicker drying of biomass, a cumbersome agricultural process.

In order to facilitate hybrid and bulk drying with reduced drying time, enhanced quality and without fungal contamination of agro-products, integration of two modes of heat source is developed with auto-control system. Biomass hot air generation system consists of efficient combustion chamber cum heat exchanger and hot-air distribution ducts. Biomass consumption rate is 15-17 kg/h with coconut husk as feedstock. Solar tunnel dryer consists of semi cylindrical tunnel shaped drying chamber with trays and movable trolley structure for loading copra and turmeric about 1.5-2 tonnes per batch. The auto-controlled mechanism will maintain the constant drying environment (desired temperature and relative humidity) throughout the drying period, by utilizing heat gain from solar dryer during sunshine hours and from biomass hot air generation system during off-sunshine hours and rainy days.

The technology gives the following unique facilities:

- Facilitates continuous drying operation (24x7) with controlled drying environment under two modes of heat source; solar and biomass.

- Efficient biomass combustor suitable to various biomass as fuel such as coconut husk, coconut shell and wood logs with heat exchanger has higher efficiency (19 %) than conventional combustors (10 %).

- Auto-control mechanism developed for both biomass hot air generation system and solar tunnel dryer for maintaining desired temperature and relative humidity levels inside the dryer to obtain better quality products

- Single drying chamber utilize the heat effectively from solar mode during sun shine hours and biomass mode during off-sun shine, rainy and cloudy hours

- Suitable to dry copra, medicinal plants, turmeric, other agro and food products with hygienic environment and enhanced quality compared to conventional open sun drying method.

The technology scores above existing solutions because frequent supervision and monitoring is not required during drying operation compared to open sun drying method and savings in drying time of about 35% than solar tunnel drying and 70% than open sun drying method. Besides, cost of drying is about Rs.1.8 per kg of copra in Biomass Solar integrated dryer, compared to Rs.5.6 per kg and Rs.2.4 per kg of copra in open sun drying and solar tunnel drying and copra yield and oil recovery are 3-4% higher than conventional method and curcumin content of turmeric increases 0.1% in hybrid dryer when compared to open sun drying.

IP Ownership: Department of Bioenergy Agricultural Engineering College and Research Institute

CIAE Aloevera gel extraction equipment

The aloevera gel extraction equipment which is under commercialization can help the women workforce extract gel with ease and absolves them of unhygienic conditions and their uncomfortable sitting position while using sharp knife.

The aloevera gel extraction equipment which is under commercialization can help the women workforce extract gel with ease and absolves them of unhygienic conditions and their uncomfortable sitting position while using sharp knife.

Continuous feed aloevera whole gel extraction equipment consists of top and bottom pair of rubber pressure rollers assembly fitted with high carbon steel blades below the upper roller and above the lower roller driven by power source (either motor or by manual rotation) through a gear transmission mechanism. The capacity of the equipment is about 200 - 225 kg/h (900 - 1000 leaves/h) when motorized and 100 kg/h (400 - 450 leaves/h) when operated manually. The saving in time is 70% of conventional method while cost is 50%.

Gel extraction is mostly carried out by women workers in unhygienic conditions and uncomfortable sitting positions by using sharp knife. The equipment is women friendly and helps in hygienic extraction of gel.

IP Ownership : CIAE Coimbatore

Wireless embedded systems for monitoring the environment of ware house and green house

The hand held system of which a prototype has been developed can evaluate the environment of ware house and green house and keep a check on whether it suits the required conditions.

The hand held system of which a prototype has been developed can evaluate the environment of ware house and green house and keep a check on whether it suits the required conditions.

The wireless sensor node development phase started with the selection of micro-controller and wireless radio for low cost and satisfying all the technical requirements. It uses wireless sensor network enabled- network coded cooperative communication.

The technology has inputs to ensures ultralow power consumption and minimizes the cost of an external radio chip. Since the wireless sensor node is battery powered, in order to reduce the overall power consumption of the sensor node ultra-low power COZIR sensor is chosen for sensing the co2, temperature and relative humidity.

The handheld type measuring instrument was designed to evaluate the condition of stored food grain manually at the required place of interest inside the warehouse. The handheld instrument was supported with a 16x2 lCD display to make it possible to monitor the conditions locally. It was interfaced with a COZIR sensor for inspecting the carbon-di- oxide, relative humidity and temperature of the stored food grain samples.

IP Ownership: Velammal Engineering College, Surapet