A newly developed biodegradable, biopolymer nanocomposite which can detect relative humidity can find application as smart packaging materials, especially for the food industry.

The food industry has an increasing need for non-toxic, biodegradable, low-cost, and environmentally friendly material for use as packaging material to replace petroleum-based material like plastics. Besides, it also needs smart and active packaging materials to detect and report food quality in a real-time fashion. Such smart and active packaging systems respond to signals while interacting with the food packaging environment. Perishable packed foods are easily damaged by the change in relative humidity.

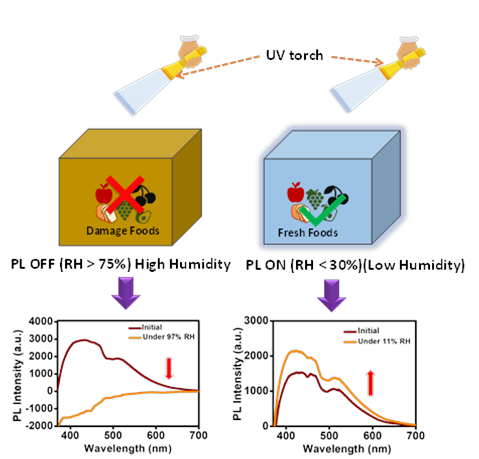

Scientists from the Institute of Advanced Study in Science and Technology (IASST), an autonomous institute of the Department of Science and Technology led by Prof. Devasish Chowdhury, Professor in the Physical Sciences Division, and his INSPIRE Senior Research Fellow (SRF) student Mr. Sazzadur Rahman have developed a smart biodegradable biopolymer nanocomposite which can detect relative humidity. In this, two biopolymers, Guar Gum (a variety of beans obtained from plant) and Alginate (obtained from brown algae), were blended with carbon dots (nanomaterial) to make a nanocomposite film that was successfully used to detect relative humidity. The fabricated nanocomposite film was an excellent smart sensor based on the fluorescence ‘on-off’ mechanisms against humidity. Their research has been published in the International Journal of Biological Macromolecules.

The nanocomposite film shows change in fluorescence in presence of high humidity. Hence, the fabricated nanocomposite film can monitor the packed food freshness using just a UV light source. “Smart and active packaging can help consumers select a fresh product without breaking the pack. Such innovative packaging boosts sales and reduces consumers' time to identify fresh food products,” said Prof. Chowdhury.

Publication link: https://doi.org/10.1016/j.ijbiomac.2022.07.008