The new method enables faster testing of mechanical strength of extremely small volumes of materials for a wide range of fields from medicine to space

A novel method to test nanomechanical properties of materials at very minute scales with high precision and accuracy has been developed by an Indian scientist in collaboration with two international institutions.

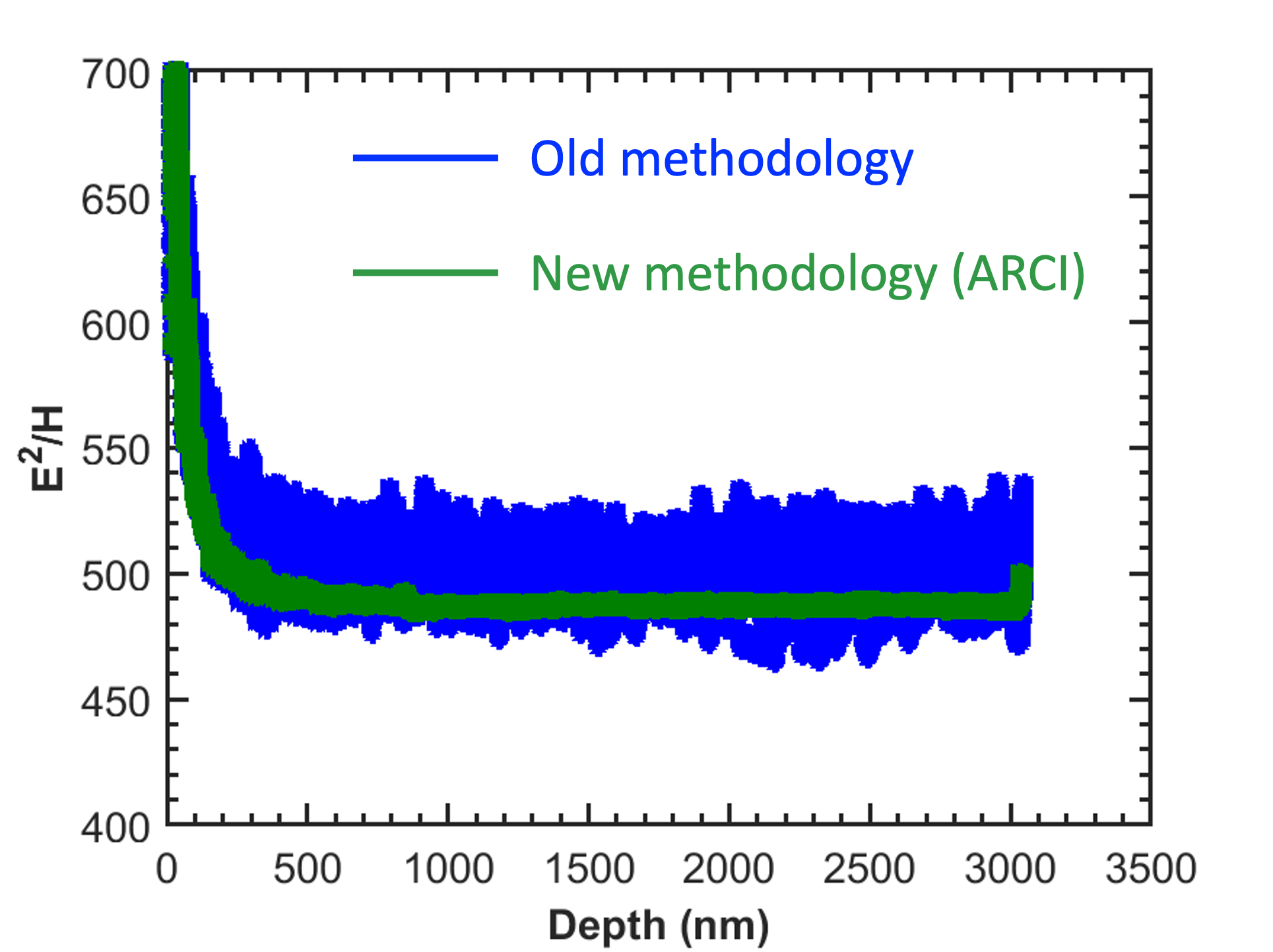

The new methodology not only significantly improves the precision and accuracy of what is known as nanoindentation technique or testing of mechanical strength, but enables testing at much higher rates, thus facilitating high throughput.

With Conventional testing methods not always feasible at nano scales, which are usually of the order of 1/100th of the diameter of a human hair, the nanoindentation technique was invented by Dr. Warren Oliver (KLA Corp.) and Dr. John Pethica (Oxford University) in the 80s and the analysis procedure was proposed by Dr. Warren Oliver and Dr. George Pharr (Texas A&M University) in their seminal work which had a huge impact on a broad spectrum of scientific research.

The technique has been widely used to measure the strength of semiconductor devices and structural materials that have ubiquitously penetrated every aspect of our daily life through electronic gadgets. The technique has been used for a wide range of applications from identifying cancerous cells to establishing how meteorites are formed in deep space.

In developing the new methodology, Dr. Sudharshan Phani of the Advanced Nanomechanical Characterization (ANC) Centre at Centre for Engineered Coatings, International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), Hyderabad, collaborated with Dr Warren Oliver at KLA and Prof. George Pharr of Texas A & M University.

The novel approach involved a combination of extensive modeling and simulation to understand the material response during an indentation test and subsequent tailoring of the methodology to improve the precision and accuracy. The modeling results have also been validated by experiments under extreme conditions.

Setting the tone for high precision and high accuracy nanoindentation measurements at much higher rates than what is traditionally possible, the new methodology is expected to impact a broad spectrum of scientific research on measuring the strength of materials at small scales. The details of methodology have been recently published in the prestigious journal in the field of materials science, ‘Materials & Design’.

Publication links: https://doi.org/10.1016/j.matdes.2020.108923 & https://doi.org/10.1016/j.matdes.2020.108924

The plot clearly shows the significant reduction in the noise levels in the measurement with the new methodology