A team of Indian scientists and research students have developed a process for large-scale manufacturing of nano-materials (Silver nanowires) that can bring down the costs to less than one-tenth of the market price.

Synthesis of one-dimensional nanomaterials like nanowires, nanotubes, and so on in large quantities is a technologically challenging task and hence makes it an expensive material. Secondly, it is necessary to get uniform nanowire diameter range with a narrow variation in the length as it helps achieve uniform coating for touch screens or other conducting coating applications.

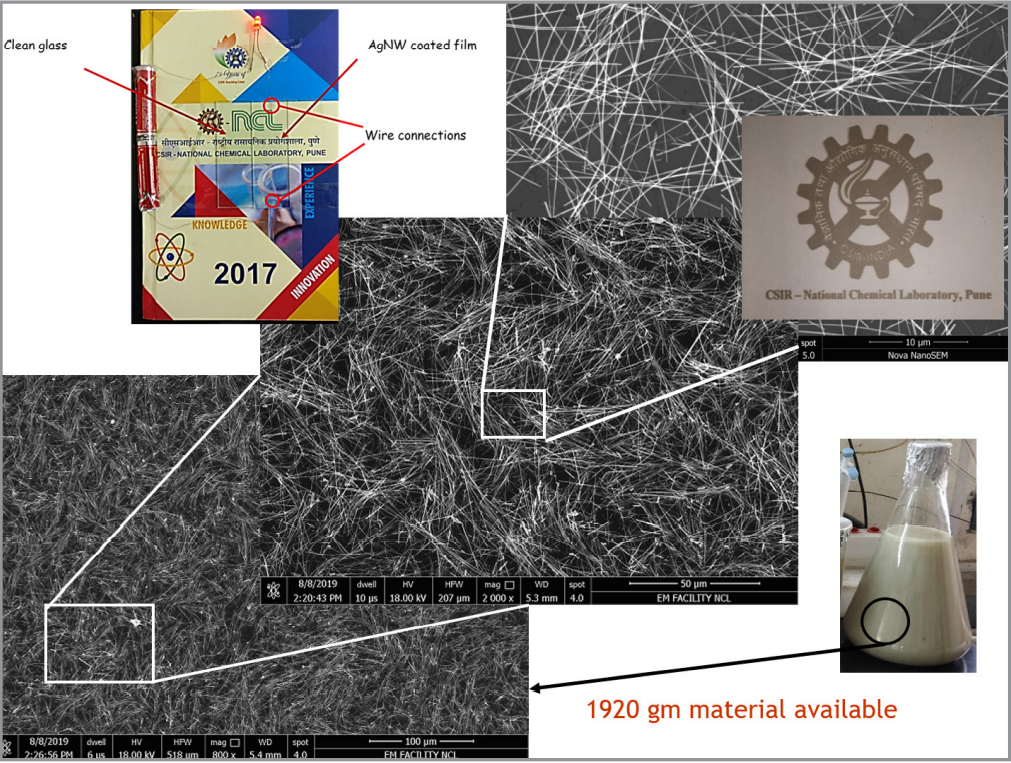

A process developed by Dr. Amol A. Kulkarni from CSIR-National Chemical Laboratory, Pune, can produce silver nanowires at the scale of 500 grams per day at the cost of 20$/gm when compared to 250$/gm to 400$/gm of market price.

It is an economical process of continuous flow manufacturing of functional nano-materials (silver nanowires) at a large scale with support from the Advanced Manufacturing Technologies Program of the Department of Science & Technology, Government of India.

The product manufactured consists of silver nanowires possessing excellent conductivity, which can be used in making conducting inks and coatings for display technologies and flexible electronics. A total of 5 national and international patents have also been filed for the novel process.

This is the first-ever continuous process for synthesizing a functional nanomaterial (Silver nanowires) efficiently with excellent product quality (aspect ratio of nanowires >1000) and at a very low cost (~20$/gm) on a large scale (500 g/day) with a footprint of the pilot plant not more than 6 sq. meters. The process is a simple, cost-effective, and scalable synthesis route when compared to existing batch manufacturing protocols that even generate a large amount of nanoparticles in suspension, which is not easy to separate from nanowires. The developed process has been tested at CSIR-NCL’s characterization facility and is in stage 8 of the Technology Readiness Level.

CSIR-NCL has licensed the process technology to Nanorbital Advanced Materials LLP (Ahmedabad) in November 2020 and has signed material transfer agreement with 3 more industries in 2021. Dr. Amol plans to further conduct testing of the developed nanomaterial in different display devices for transparent conducting applications as well as for printing of flexible electronics, including wearable electrodes.

This technology can make the Indian industries enter into the niche area of electronic chemicals and eventually open up new jobs.

The Process Temperature is more than 130 deg C. The reactants are preheated and sent to the four Multistage Multiphase reactors arranged in series, which are connected to appropriate utilities for precise control of temperature. At the top of the reactors, condensers are connected to condense fumes from the reaction. The reactant mixture travels from one reactor to other via pumps, and the product is collected at the outlet of the fourth multiphase reactor in the product tank, where it is cooled and further sent for purification.

Patent details :

1. Large Scale Continuous Synthesis of Silver Nanowires Using Bubble Column Reactor 2019-NF-0189 IN 201911046584

2. ‘Novel Multiphase Reactor And Its Use In Synthesizing Metal Nanowires 2019-NF-0189 IN 201911046584.

3. Continuous flow production of metal nanowires, EP3678804A1 (Priority 2017-09-06 • Filed 2018-09-06 • Published 2020-07-15)

4. Process for interfacial separation of metal nanoparticles or nanowires using centrifugal separators, US20210283532A1, (Priority 2017-05-01 • Filed 2018-04-30 • Published 2021-09-16)

5. A continuous flow process for the synthesis of metal nanowires using bubble column reactor, WO2021095054A1 (Priority 2019-11-15 • Filed 2020-11-12 • Published 2021-05-20)

For more details, contact Dr. Amol A. Kulkarni (9881235277, aa[dot]kulkarni[at]ncl[dot]res[dot]in).