Indian Scientists have developed analytical models that can predict topography of electrical discharge textured (EDT) surfaces, aiding their customisation for improving hip and knee implants.

Electrical discharge textured surfaces have suitable surface topography and surface chemistry to promote tissue growth and adhesion. Surface topography prediction is important in EDT surfaces as the process generates characteristically random surfaces that are very difficult to predict. To optimise the EDT surface topographies for different applications such as orthopedic implants and rake face of tool inserts, the topography is needed to be known at design stage through suitable methods of topography prediction.

To this end, Dr. Suhas S. Joshi, Professor at the Indian Institute of Technology Bombay, Mumbai, developed analytical and numerical models for prediction of surface topography which were validated against experimental data. The work supported by the Advanced Manufacturing Technologies program of the Department of Science & Technology, GoI, and aligned with the ‘Make in India’ initiative has been recently published in esteemed journals such as ‘Surface Topography: Metrology and Properties’ and accepted for publication in the ‘Journal of Materials Processing Technology.

The analytical and numerical simulation of surface topographies generated using EDT, which was in good agreement with experimental data, can be developed into modules which could be used for surface texture prediction at different parameter combinations. The topography prediction modules could help efficient and low-cost generation of textured surfaces with higher protein absorptivity as compared to non-textured surfaces, which is favourable for orthopaedic implants like hip and knee implants. The developed technology is in level 6 of the Technology Readiness Level.

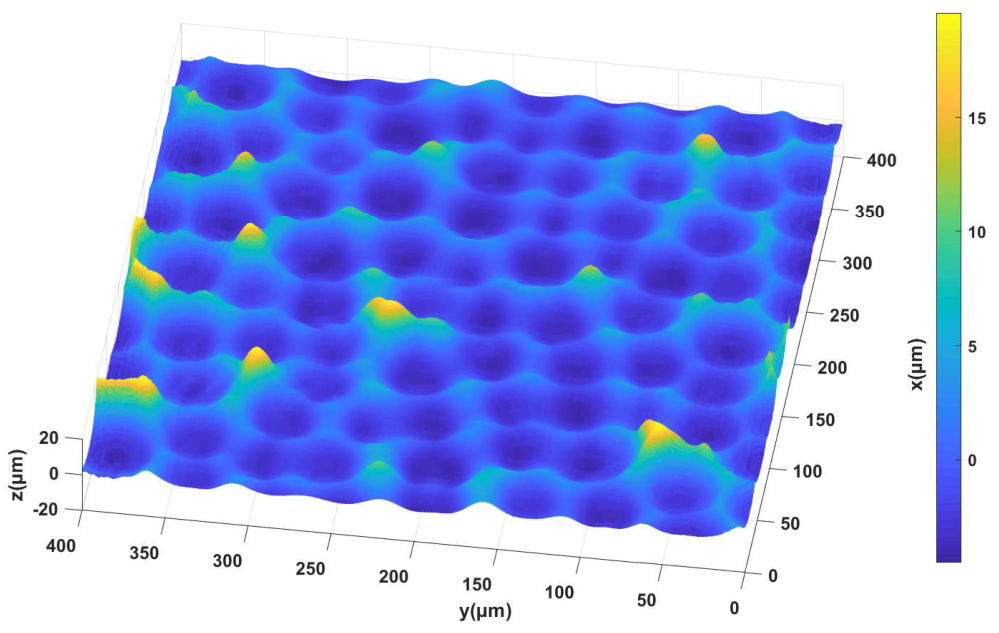

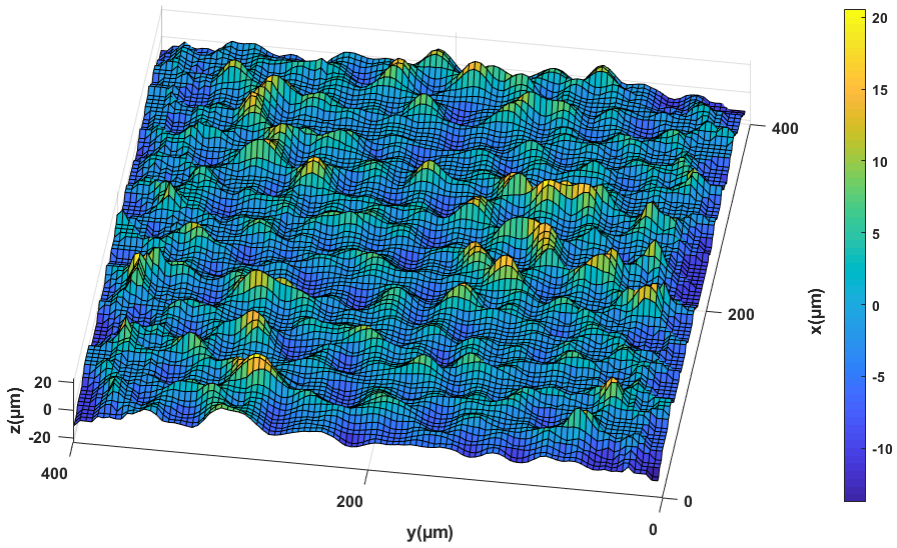

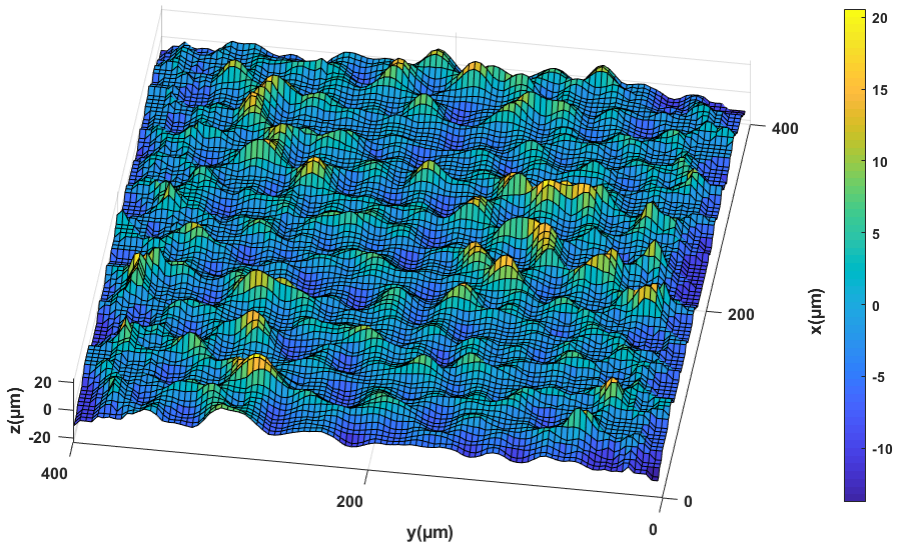

Figure 1: Comparison between (a) analytically simulated, (b) numerically simulated, and (b) measured surface topographies at a parameter combination of (10 A, 20 µs, 50 V) (Ref: Journal 1)

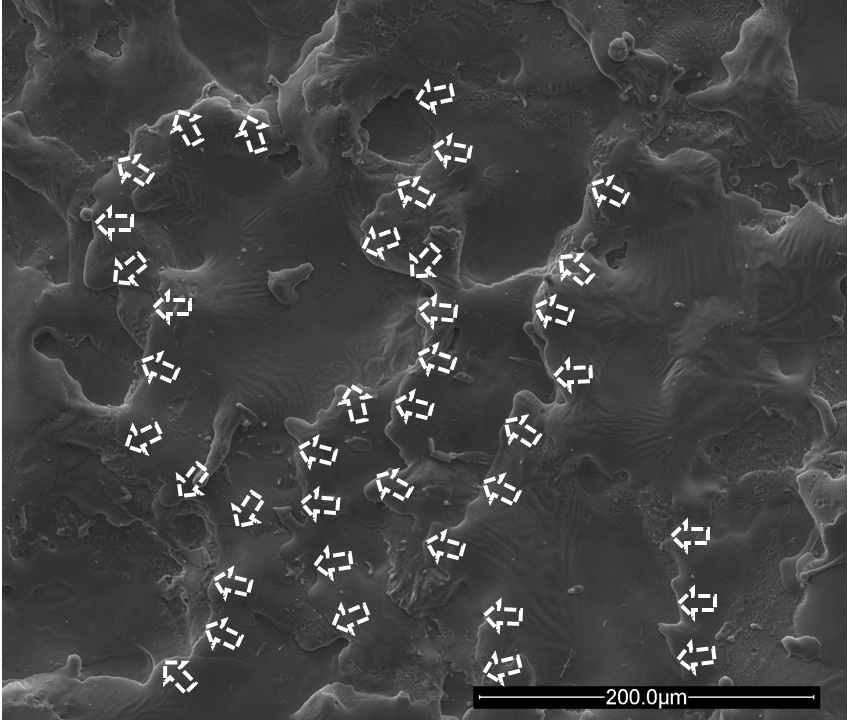

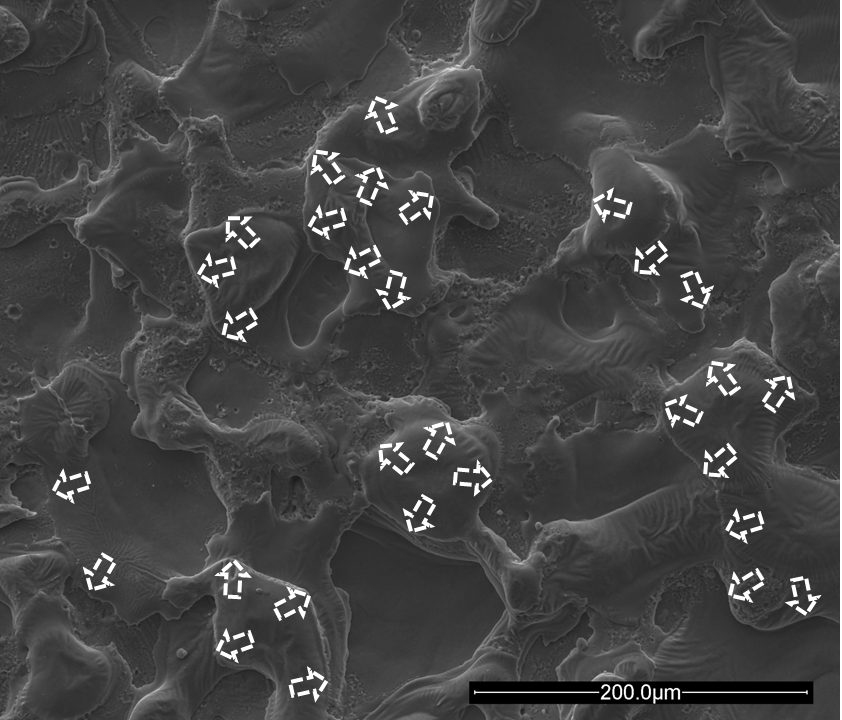

Figure 2: SEM images of (a) cylindrical-face EDTed (sea-waves-like-patterns)and (b) circular-face EDTed (lunar-craters-like patterns) surfaces at a parameter combination of 10 A, 20 µs, and 3.92 m/min showing molten material resolidification directions (Ref: Journal 5)

Publication details

- S. Jithin, U. V. Bhandarkar, and S. S. Joshi, Characterization of Surface Topographies Generated using Circular- and Cylindrical-Face EDT, Surface Topography: Metrology and Properties, vol. 8, no.4, 045018, 2020.

https://doi.org/10.1088/2051-672X/abc320 - S. Jithin, U. V. Bhandarkar, and S. S. Joshi, Surface Topography Generation and Simulation in Electrical Discharge Texturing: A Review. Journal of Materials Processing Technology, 298, 117297, 2021. https://doi.org/10.1016/j.jmatprotec.2021.117297

For more details Dr. Suhas S. Joshi (9920177527, ssjoshi[at]iitb[dot]ac[dot]in) can be contacted.