In a small freezing cold village called Thiksey in Leh, the extremely cold temperatures at the place has led people to cut down trees in large amount to obtain wood for burning in cold winters. Electricity generation through solar panels is well suited in summers, but during winters, the absence of sunlight hampers the production of solar power.

A new sustainable technology solution called Nilaya housing may soon bring them some comfort from the cold without worries of incurring high energy loads and costs of heating during the cruel winter months when the temperature hits the mark of -30 deg celcius in winters.

The technology developed by SMEF’s Brick School of Architecture

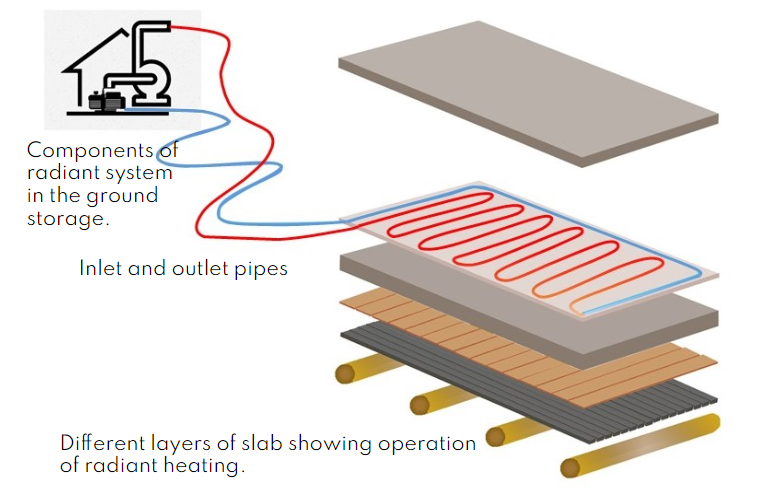

and Pimpri Chinchwad College of Engineering is a radiant heating system that uses biogas to heat water in a closed system of pipes. The water transfers heat by circulation and is accompanied with a radiant floor heating system. The technology has received the Solar Decathlon Award by the IUSSTF, an autonomous bilateral organization jointly funded by both the Governments of India and the USA that promotes Science, Technology, Engineering and Innovation for which the Department of Science & Technology, Government of India, and the U.S. Department of State are the respective nodal departments.

Developed mainly to overcome the extreme cold temperatures of Leh – Ladakh, the innovation will obviate the need to cut down trees in Leh Ladakh, to purchase the wood in bulk for heating the Bukhari, and also prevent any greenhouse effect generated due to burning of coal and emitting out carbon on higher level.

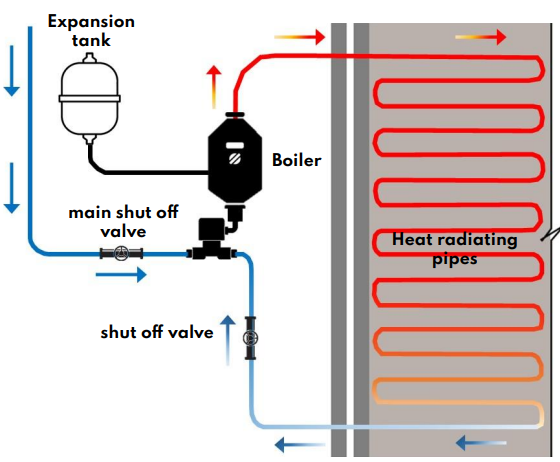

The mechanism of the radiant heating system involves supply of generated greywater to the boiler with an external source. This water is then heated inside the boiler with biogas as eco-fuel. The water is heated up to 60 deg maximum and then transferred to the pipes that are laid under the floor in the spaces. The pipes carrying the hot water get heated and radiate the heat upwards. Here, the flooring system also plays an important role. The radian pipes are covered with materials with high conductivity from top, and the layer beneath the pipes has a material with low conductivity so that the heat does not radiate to the ground in the opposite direction. The water in the pipes, after dissipating all its heat to the space, is collected into the boiler tank with the help of pump. This is carried out with a thermostat that turns the pump on, which again transports the water back to the boiler. The same water is used in the cycle for 15-20 days.

The radiant floor heating systems currently used in the area utilise electricity to heat up the water at frequent intervals to keep the indoor environment warmed up. This increases the usage of electricity and hence leads to increase in the demand load of the building. In the new system, electricity was replaced with biogas for a more sustainable solution to the heating problem, as abundant amount of cow dung is locally available.

The net-zero structure will need a digester tank with a connection to the burner that will help passage of the gas and also skilled workers to lay down the pipes under the floor and to connect these pipes to the thermostat and water heating system.

SMEF’s Brick School of Architecture

and Pimpri Chinchwad College of Engineering is working with an NGO called ASEEM Foundation to implement the technology in Leh.