A newly developed integrative-modular-onsite toilet treatment system that provides the complete solution for human waste coupled with resource recovery could help unlocking the circular economy potential in sanitation. It could recover valuable nutrients such as N, P, K as commercial-grade chemicals from urine, convert carbon-based soil amendments from feacal sludge and recover reusable water from urine.

Environmental sanitation is a significant public health issue in India that is still lagging far behind many countries. The government has embarked on a mission to make India Swachh in the coming years. Undiluted human waste (urine & faeces) is a potential source of Nitrogen (N) non-renewable Phosphorous (P) and a good soil amendment. Presently the valuable nutrients are flushed into the sewer systems. About 80% of N & 60% of P load to wastewater treatment plants are contributed by human urine. On the other hand, India imports about 80% and 100 % of phosphorus and potassium respectively for agriculture and often pays a very high price. Nutrients from urine can cater to about 22% of the global phosphorus demand. These nutrients are flushed into sewer which is usually treated for removal and not recovery. Many attempts to deal with sanitation issues have faced challenges which are fuelled by inadequate water and improper maintenance. Some of them include elimination of open defecation by providing toilets. However, the toilets need new technology to be clean and green.

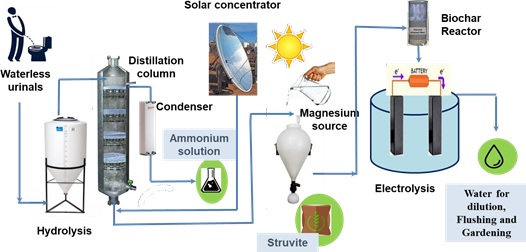

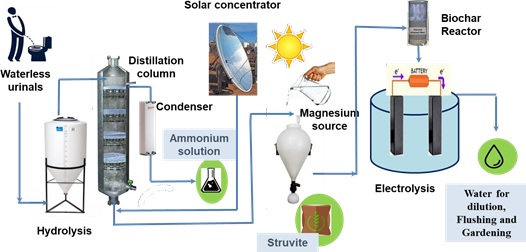

Dr. Indumathi M Nambi, Professor, Department of Civil Engineering, Indian Institute of Technology, Chennai and Dr. M. Devasena, Professor, Department of Civil Engineering, PSG Institute of Technology and Applied Research, Coimbatore found an integrated process of ‘source separation’ of urine followed by harvesting of Nitrogen in the form of ammonium liquid (Distillation), Phosphorus in the form of struvite (Automated Struvite Reactor) and Carbon as soil amendment from solid waste (Black solder Fly Larvae Composting Technique).

The complete zero energy process starts by collecting liquid and solid resources from public restrooms where waterless urinals and urine diversion toilets (UDTs) are maintained. The collected urine is transported to a central collection point where it undergoes biological urea hydrolysis to produce a liquid suitable for ammonia removal. After recovery of ammonium from source separated urine, Phosphorus is harvested in the form of struvite in the automated struvite reactor fitted with magnesium dosing pumps and an overhead stirrer. Enhanced carbon rich compost can be achieved from the solid waste obtained from twin pit toilets/UDTs. This is followed by recovery of non-potable water through electrochemical system. A spreadsheet-based life cycle assessment model was developed by the researchers to track the impacts of design and operational decisions. The process has been recently published in the journal Biomass Conversion and Biorefinery.

The integrated zero energy process that produces NPK and enriched carbon and recycled water is a holistic approach which can be upscaled into a profitable entrepreneurial element.

Publication details: DOI 10.1007/s13399-022-02452-x

Patent details: 411075/Integrative-modular onsite urine treatment unit for recovery of water and green chemicals

Implementation & Impact

Location: IIT-Madras Year of Implementation: 2020

Scale: 250 Litres/day feed

Water Saved: 1000 m3/year

Ammonia Generated: 500 Liters

For a 500 LPD unit, we generate