A novel method for directly synthesizing Carbon nanotubes (CNTs) on glass substrates at a temperature of 750 °C could help energy research, biomedical fields, and optoelectronics.

Carbon nanotubes (CNTs) are pivotal in advancing modern technology by showcasing extraordinary properties. They have found applications in diverse fields, including rechargeable batteries, flexible electronics, aerospace, transparent electrodes, touch screens, supercapacitors, and medicine. However, conventional CNT synthesis methods require high temperatures (~1000 0C) and metal catalysts (Fe, Co, and Ni). These catalysts pose biocompatibility concerns for potential biomedical applications. The challenge of removing these catalysts from CNTs adds a significant cost, highlighting the urgent need for cleaner, more sustainable CNT synthesis methods - an exciting frontier in the realm of nanotechnology.

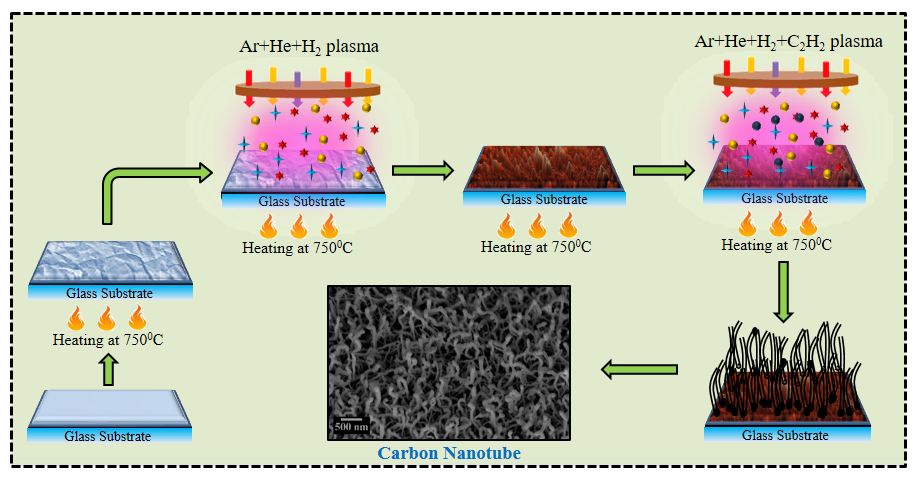

Researchers at the Institute of Advanced Study in Science and Technology (IASST), an autonomous institute of the Department of Science and Technology (DST), Government of India, have pioneered a novel method for directly synthesizing CNTs on glass substrates at a temperature of 750 °C. The experiment is performed using the Plasma Enhanced Chemical Vapour Deposition Technique (PECVD), where plasma is generated using a specially designed spiral-shaped fused hollow cathode source. This innovative process circumvents the need for elevated temperatures and eliminates the necessity for a transition metal catalyst. Furthermore, this synthesis is executed under atmospheric pressure, adding commendable cost-effectiveness to its advantages compared to counterparts in the field.

Several factors, including the plasma characteristics, substrate composition, substrate temperature, and plasma pre-treatment of the substrate, significantly influence the CNT growth. Optimally, the pre-plasma treatment of the glass substrate at an elevated temperature enhances the surface area, exposing a more significant amount of its constituent elements directly to the surface. Among all the elements within the glass, sodium (Na) emerges as the primary catalyst for initiating CNT growth, and analysis evidences the same. It has also been observed that the Na present in the as-grown CNTs can be easily removed by washing the Na-containing CNTs with deionized water.

In essence, this study unveils a novel atmospheric pressure PECVD process for synthesizing CNTs, enabling the production of clean CNTs suitable for applications in energy research, biomedical fields, and optoelectronics. The finding marks a significant stride towards addressing challenges in CNT synthesis and advancing their application in diverse technological fields.

Patent filled: “A Process for Single-Step Synthesis of Carbon Nanotube on Glass Substrate”, Jyotisman Bora and Arup R. Pal, (Indian Patent Application No. 202331043095)

Publication Link: https://doi.org/10.1016/j.apsusc.2023.158988)

For more details contact Dr. Arup R. Pal: E-mail: arpal[at]iasst[dot]gov[dot]in

Figure 1: Different steps involved in the growth process of sodium catalysed growth of carbon nanotubes by atmospheric pressure PECVD