A temperature and flow control ultrasonic spray (tFOCUS) System for Nano-Drug Formulation could improve the efficacy of herbal medicines by enhancing the bioavailability of the herbal ingredients of the medicines. This device could improve cost-effectiveness and therapeutic efficacy of medicines involving expensive phytomolecules.

The delivery of herbal therapeutic ingredients as drugs in conventional forms shows variable and non-uniform absorption. Lower duration of residence in the stomach and varying gastric emptying time may limit the bioavailability of these drugs. They are also highly sensitive to temperature, atmospheric moisture. Their hygroscopic nature affects the particle-particle interactions, leads to poor water solubility and contributes to their poor flow in systematic body fluid circulation.

To overcome such limitations, herbal drugs can be encapsulated with suitable biopolymers as nanocarriers. The nanocarrier can significantly enhance the gastric emptying time and deliver higher amount of drug for a sustained period in the stomach. In addition, the amount of drug required to be incorporated to nanocarriers is much less than required when encapsulated in a tablet. This is very useful when using expensive phytomolecules. Optimal use of phytomolecules improves the cost-effectiveness and therapeutic efficacy of the product.

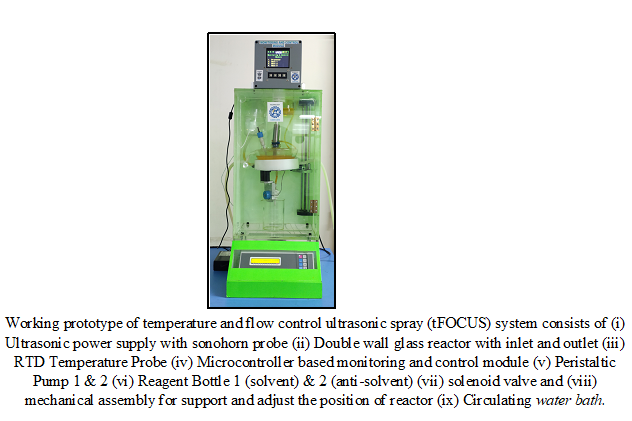

Keeping this in mind, Dr S. Prabhakaran, Sr. Scientist at CSIR-Central Scientific Instruments Organisation (CSIO) Chennai Centre, has developed a new prototype of temperature and flow control ultrasonic spray (tFOCUS) system with support from the Advanced Manufacturing Technologies programme of the Department of Science & Technology (DST), Government of India, and aligned with the ‘Make in India’ initiative to enhance colloidal stability of poorly water-soluble herbal extracts.

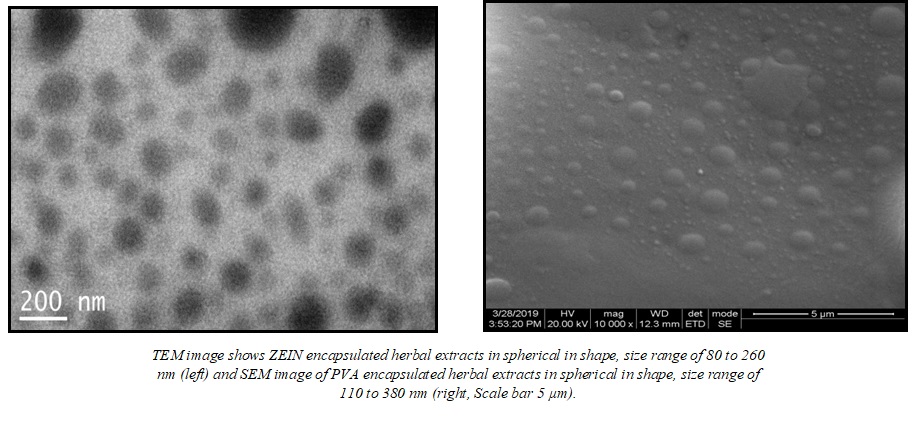

The prototype has been validated using commercial AYURSULIN capsule used to treat type-II diabetic as model drug. To enhance the bioavailability tFOCUS system, prepare nano-encapsulation of all five herbal extracts using polymer (ZEIN/PVA). The samples were spherical in morphology, nanoscale range and good colloidal suspension in water as compare to bare herbal extracts. A feasibility study was made to develop a colloidal stable nanocarrier system containing a mixture of herbal extract like Curcuma Longa, Andrographis, Paniculata, Tinospora, Cordifolia, AegeleMarmelos, Emblica Officinalis in equal ratios nano encapsulating using different types of wall polymers.

The prototype of tFOCUS system enhanced the solubility of poorly water-soluble multi-herbal extracts using nanoencapsulation biocompatible polymer in rapid reaction process at room temperature, which is compactable with temperature-sensitive therapeutic active ingredients.

This unique nano-drug particle synthesis system based on acoustic cavitation can provide continuous large scale compared to present microencapsulation technologies such as mechanical stirrer assisted antisolvent addition method, spray dry methods, and high-pressure homogenization method production with less power consumption, rapid reaction time leading to faster sample preparation. It enables nanosize-encapsulation of multi-herbal components at variable operating temperatures (10°C to 80 °C). With ease to control size & shape of particulate by control flow rate, temperature and ultrasonic energy, this easy to handle & portable system is in the 4th stage of Technology Readiness Level TRL-4.

“Pharmaceutical and Food industries and Scientific Instruments manufacturing industries have shown interest to take up this technology for commercialization. We will provide incubation centre from CSIO Chennai Centre and manpower training for system operation and optimization of new drug formulation,” says Dr S. Prabhakaran. He has allied with BAL Research Foundation (BRF) Bangalore for further upscale of the technology.

For more details, Dr S. Prabhakaran (9894043889, prabhakarans[at]csio[dot]res[dot]in) can be contacted.