Soon automobile servicing industry, food industry, and other low and medium scale enterprises can have a smart, affordable electric field-assisted membrane separation device at their disposal for oily waste water treatment.

Low-income group users mostly cannot afford the high cost of treatment technologies available for handling oily wastewater generated at their source points. As a result, large amount of untreated oily wastewater is discharged into the aquatic bodies without following the guidelines of the Pollution Control Board.

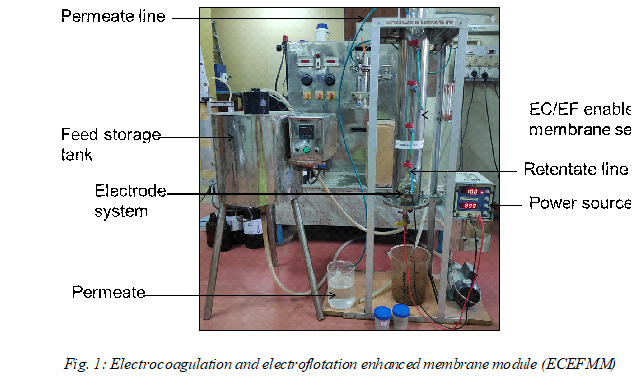

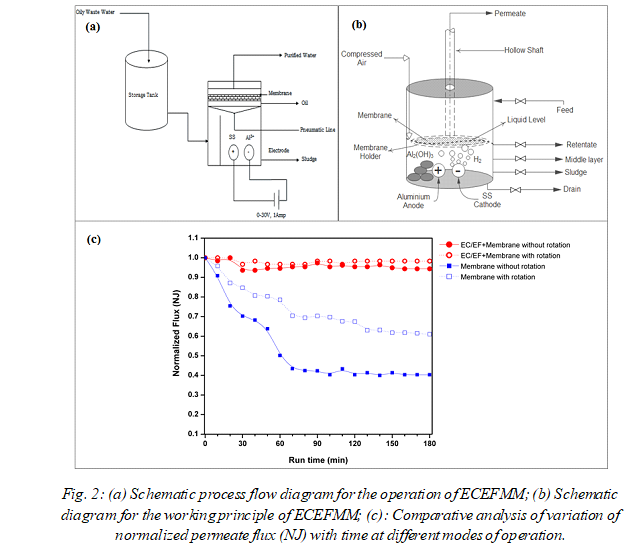

The technology developed by Dr Chiranjib Bhattacharjee, Professor at the Chemical Engineering Department in Jadavpur University, Kolkata, uses a combination of Electrocoagulation and Electroflotation Enhanced Membrane Module (ECEFMM) techniques for waste water treatment. Electrocoagulation is a waste water treatment technique that uses electrical charge for changing the particle surface charge, allowing suspended matter to form aggregates, and electroflotation is the separation of suspended particles from water using hydrogen and oxygen bubbles generated by passing electricity through water.

In the developed module, electrocoagulation and electrofloatation are adjoined with membrane in a single indigenous setup. The turbulence created because of the hydrogen bubbling through the feed medium or the waste-water resists the deposition of oil over the membrane. The synergistic effect of hydrogen bubbling and rotation of the membrane module creates substantial turbulence within the solution and on membrane surface. On application of electric field during membrane separation, membrane fouling is substantially reduced, and membrane longevity is also enhanced by restricting the membrane ageing for prolonged time period. Thus, it requires less frequent membrane replacement, thereby reducing the maintenance costs to a great extent.

The innovation being an economically feasible wastewater treatment technology (both in terms of capital and recurring investment) for low-scale and medium enterprises, has a good market potential. Moreover, unlike other conventional treatment, it can break the highly stable oil-water emulsion through electric discharge and simultaneously separates oil from water with high efficiency. Besides, by integrating the electrochemical process setup with the membrane module in a single hybrid ECEFMM setup, one process has been eliminated. This significantly lowers the initial capital investment expense along with the additional advantage of reduced installation area requirement.

This technology developed with support from the Advanced Manufacturing Technologies programme of the Department of Science & Technology (DST), Government of India requires minimal manpower and does not need high-end technical adequacy for its operation, thus reducing the operational expense to a large extent. The recovered spent oil after oily wastewater treatment can be further used as an industrial burner oil, furnace oil, mould oil, hydraulic oil and so on. Thus, it creates a huge revenue generation scope for low-income groups by selling this collected spent oil. In a zone of densely concentrated garages, installation of one setup will serve the purpose of wastewater treatment and thereby extend the opportunity towards other low-income group users to control the water pollution level within PCB regulations. It is aligned with the ‘Make in India’ initiative. The validation and testing of the prototype has been successfully accomplished, and the pilot-scale validation and testing is on the verge of completion.

So far, the separation technology running in different sectors for treating such oily wastewater involves the installation of an electrolytic cell or DAF followed by membrane unit. However, installing two separate units requires a high footprint area compared to the present unit, where two unit operations are being assimilated in a single unit, said Dr. Bhattacharjee.

This prototype innovation has proceeded towards level 6 of the Technology Readiness Level, and Dr. Chiranjib Bhattacharjee has partnered with Concepts International for industrial collaboration and scale-up of the innovation. He plans to further carry out a field run with the pilot-scale module, networking and field installation, and Commercialization of the equipment through start-up.

For more details, Dr. Chiranjib Bhattacharjee (9836402118; c[dot]bhatta[at]gmail[dot]com )can be contacted.