In fluid dynamics, drag is the friction force due to relative motion between an object and the fluid. Two important factors determine this frictional force, viscosity which is the property of the fluid and flow condition. In the case of pumping, frictional force manifests as pumping power required to overcome this frictional force. When the flow is smooth (laminar flow), frictional force is low; under chaotic turbulent flow condition, which consists of rapidly varying whirling flows (turbulent vortices), frictional force is high. Reduction of this frictional force, also called Turbulent Drag, can help in reducing pumping cost in many practical situations such as crude-oil pumping over long distances. It has been found by adding polymers, at very low concentration, TDR can be achieved. This has led to extensive research in understanding the TDR mechanism and identifying good polymers for TDR application.

In fluid dynamics, drag is the friction force due to relative motion between an object and the fluid. Two important factors determine this frictional force, viscosity which is the property of the fluid and flow condition. In the case of pumping, frictional force manifests as pumping power required to overcome this frictional force. When the flow is smooth (laminar flow), frictional force is low; under chaotic turbulent flow condition, which consists of rapidly varying whirling flows (turbulent vortices), frictional force is high. Reduction of this frictional force, also called Turbulent Drag, can help in reducing pumping cost in many practical situations such as crude-oil pumping over long distances. It has been found by adding polymers, at very low concentration, TDR can be achieved. This has led to extensive research in understanding the TDR mechanism and identifying good polymers for TDR application.

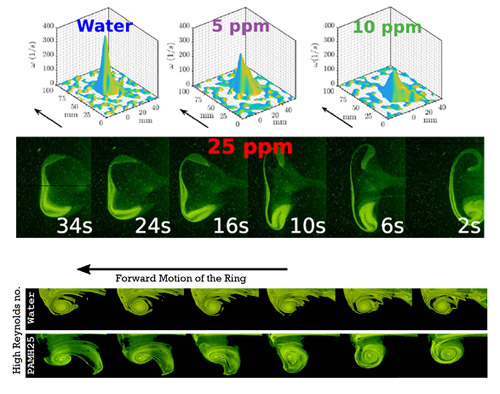

Scientists from the Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR), an autonomous institute of the Department of Science & Technology, Government of India, have carried out controlled experiments with the objective of the understanding mechanism of polymer turbulent drag reduction. In their experiments, they have studied formation and propagation of vortex rings (for example, dolphin’s bubble ring), which is a caricature representation of the turbulent vortices.

They demonstrated that when the relaxation time of the polymer used for TDR is same order of magnitude as the flow time scale, the elastic energy stored in the stretched polymer is released back into the flow field that terminates frictional loss at a larger scale and thus reduces turbulent frictional loss in the flow. They also show polymers in the fluid resists roll-up of shear layer into a coherent structure ( impede the formation of turbulent vortices), and polymer spreads the vorticity over a larger area, thereby reducing turbulent drag. Numerical models that strive to simulate TDR could first reproduce these results, to show their simulations are capable of modeling polymer effect in the flow. The research published in the journal Chemical Engineering Science could serve as a benchmark for numerical simulations used to model polymer solution behavior inflow.

In their experiments, the team used water, an aqueous solution of polyethylene oxide (PEO) (400 ppm), hydrolyzed polyacrylamide (PAMH) (in 5, 10, and 25 ppm concentration) and PAMH with salt (25 ppm with salt) as working fluids. Among them, water is a Newtonian fluid, and other non-Newtonian fluids have relaxation time varying from few milliseconds to order of tens of seconds.

According to the team, the inhibition of the roll-up process and the reversal of the vortex ring could shed some light on the interaction between dissolved polymers and turbulence that leads to drag reduction.

Publication link:

https://doi.org/10.1016/j.ces.2020.115767

https://doi.org/10.1016/j.ces.2020.115961

For more details contact Prof. K.R. Sreenivas (krs[at]jncasr[dot]ac[dot]in; 9449018203)