A new non-precious metal-based bi-functional electrocatalyst (capable of catalyzing two different types of reactions) can decrease cost and increase the efficiency of metal air batteries.

With the rise in demand for different energy sources, worldwide efforts are being made to develop different kinds of energy devices, such as lithium-ion batteries, lead-acid batteries, redox flow batteries, lithium-air batteries, zinc-air batteries, etc. sodium-ion batteries, fuel cells, and supercapacitors.

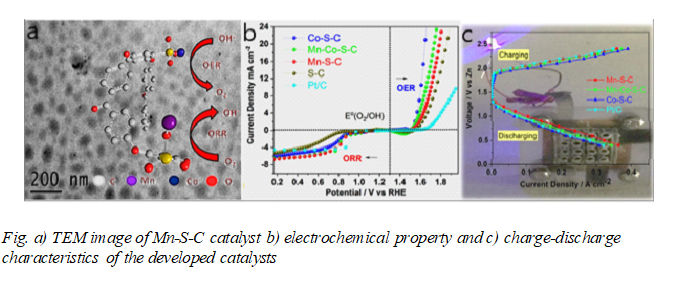

Among them, Zn-air batteries have drawn significant attention due to their low cost and high energy density. They are compact power sources for portable electronics and electric vehicles and energy storage devices to manage energy flow among renewable energy generators, such as wind turbines, photovoltaic panels, electric grids, and end-users. However, a major challenge for such batteries is catalyst development. A bi-functional catalyst works for oxygen reduction while discharging the battery, and the same catalyst helps in oxygen evolution reaction during the charging cycle. Most of the conventional catalysts available consist of noble metals in their composition, making the batteries costly.

International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous R&D Centre of Department of Science and Technology (DST), Govt. of India, has developed the cost-effective electrocatalyst by anchoring transition metal ions into the sulfur-doped carbon framework via carbonization of a polymer called sPEEK (sulphonated polyether ether ketone). This catalyst synthesis method can also be used to recycle used ionomers (polymer composed of both neutral repeating units and ionized units).

The scientists have used an ion-exchange strategy that positions the metal ions in the carbon framework homogeneously, limits the particle size and offers control on composition and size at a very low loading of transition metal. Cost-effectiveness is thus achieved by low loading of transition metal, high activity, and high cycling stability compared to many of the catalysts earlier reported in the literature.

The catalyst also leads to reduced voltage polarization, enabling higher energy efficiency and a stable charge-discharge characteristic. The results obtained were comparable to that of conventionally used noble metal-based catalysts with metal loading of 20% or higher. The research has been published in ACS Applied Energy Materials

Publication link: DOI:10.1021/acsaem.9b01217

For more details, Dr. K. Ramya (ramya[at]arci[dot]res[dot]in) can be contacted