Researchers have developed smart IoT-based machine for welding ferrous tubes faster than conventional fusion welding or solid-state processes presently used with less consumption of energy.

As manufacturing industries move toward advanced technologies, there is a requirement to minimise energy consumption and automate the welding process to avoid human-induced errors and also manufacture products swiftly in an eco-friendly manner.

Dr. S. Arungalai Vendan, Professor, Electronics, and Communication, School of Engineering, Dayananda Sagar University, Bangalore developed the Internet of Things (IoT) integrated machine titled “Magnetically Impelled Arc Butt Welding Equipment" embedded with sensors for sound, vibration, arc light intensity, temperature as well as smoke, along with processors for abstracting data for predicting the quality of the welding. The low-cost IoT integrated machine was supported by the Department of Science and Technology,

Dr. Vendan who obtained his Ph.D. in MIAB welding explored the process at Welding Research Institute, Bharat Heavy Electrical Limited, Tiruchirappalli, India for pressure part applications. Observing the huge potential of adopting the process for various industrial applications to join ferrous tubes, the investigator came up with the idea of developing a low-cost IoT integrated MIAB machine for joining ferrous tubes.

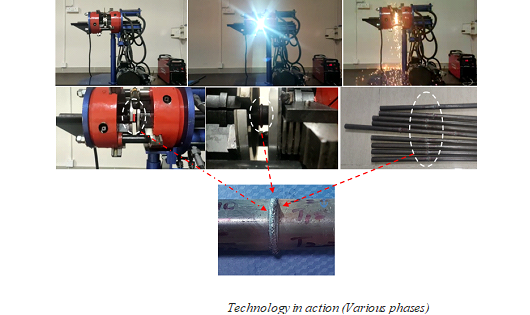

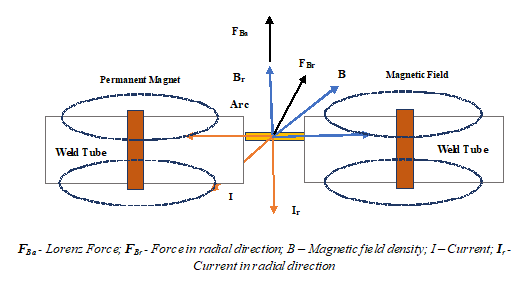

Magnetically Impelled Arc Butt (MIAB) welding involves striking of an arc between two coaxially placed tubes, followed by interaction of the axial component of arc current and radial component of a magnetic field that causes a force called Lorentz force. This force acts on the arc and impels it around the joint line with an approximate linear speed of 200m/s that uniformly heats the tube surfaces upto the highest temperature at which it is solid (solidus temperature). The softened tube edges (butt ends) are then forced into penetration by forging to form a weld.