A new smart gel-based sheet using three-dimensional (3D) printing technology that can self-roll into a tube during surgery to form a nerve conduit could help reduce the complexity of surgeries and aid rapid healing of nerve injuries.

The gold standard for the treatment of peripheral nerve injuries is still autografts. Bioresorbable polymer-based conduits are being explored for clinical use as alternatives. But these treatment strategies suffer from several limitations, such as donor site morbidity in the case of autografts and the necessity for sutures that demand highly skilled microsurgeries, and additional complications posed by sutures.

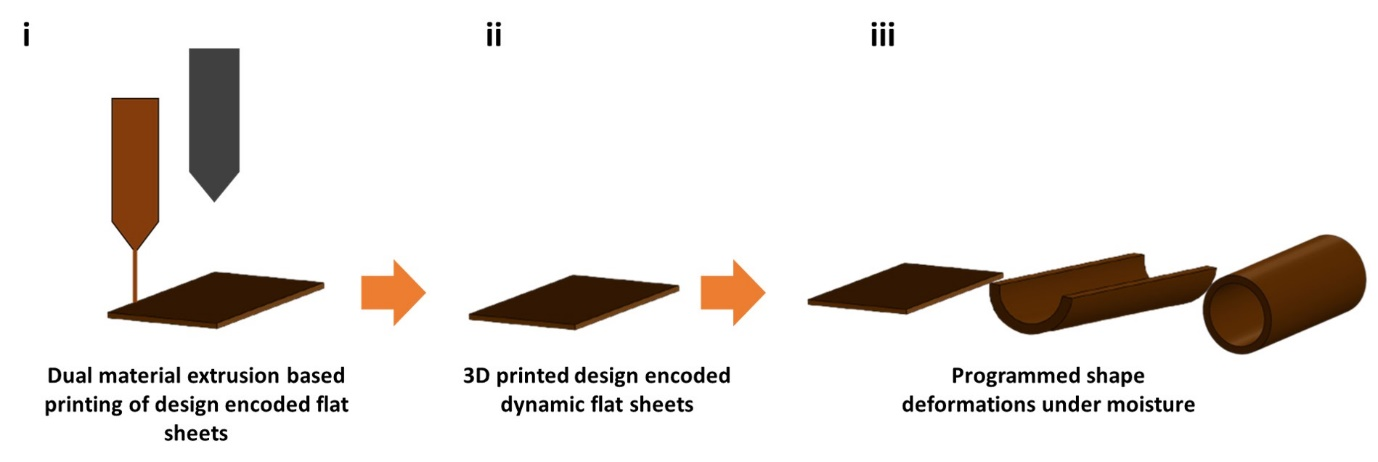

These clinical shortcomings motivated researchers at the Indian Institute of Science (IISc) in Bengaluru to design a smart gel-based sheet using three-dimensional (3D) printing technology that can self-roll into a tube during surgery to form a nerve conduit. In 3D printing, a virtual model of the part is created using design software, and the part is then fabricated using a 3D printer by layer-upon-layer deposition of the material. 3D printed parts can further undergo a shape change on demand upon activation after fabrication. Such technologies are now widely known as four-dimensional (4D) printing, where time is the extra dimension.

In a recent study, the team at IISc, led by Professor Kaushik Chatterjee, engineered a bilayered gel sheet by 3D printing in pre-defined patterns from two gels. The gel formulations were selected to swell differently. When the dried gel sheet was immersed in water, it rapidly swelled and curled into a tube. The folding behavior and final shape of the gel could be programmed to generate tubes of desired dimensions, which could be predicted by computational modeling. The gel sheets were then coated with thin nanometer-scale fibers to enable the body’s cells to adhere to the gel sheet.

Scheme 1: Fabrication of 4D printed hydrogel conduit with programmed shape deformations. (i) 3D printing of gels of defined formulation with precise patterning based on computational design, (ii) 3D printed gel sheet, (iii) Programmed shape deformation with moisture uptake.

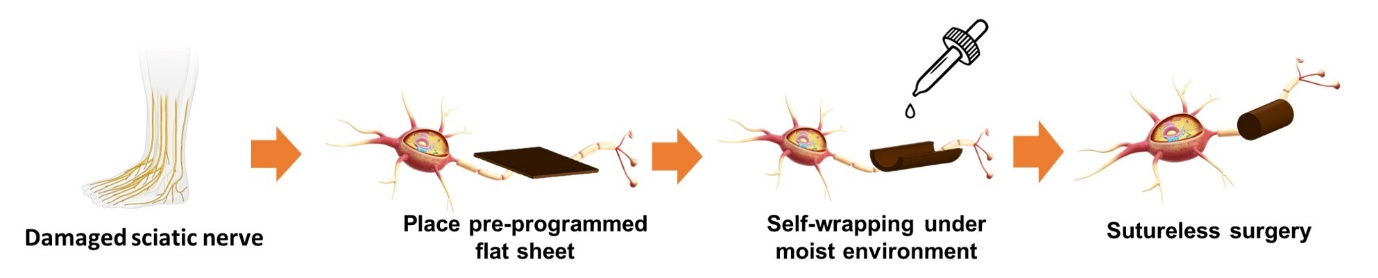

The team at IISc worked closely with researchers at the Indian Institute of Technology at Roorkee and Maharishi Markandeshwar University to test the 4D printed conduits for repairing and regenerating a 2 mm gap in the sciatic nerve of rats. The shape-morphing sheets were placed under the defect region of the nerve and stimulated to wrap the defect site to form a conduit around the nerve without suturing. The nerve ends could grow through the implanted conduit. There was a remarkable improvement in nerve regeneration measured up to 45 days in the rats when the 4D printed nerve conduits were used. The team consisting of Akshat Joshi, Saswat Choudhury, Vageesh Singh Baghel, Souvik Ghosh, Sumeet Gupta, Debrupa Lahiri, G.K. Ananthasuresh, Kaushik Chatterjee reported its findings in a paper published in Advanced Healthcare Materials. This work was supported by the Science and Engineering Research Board (SERB), a statutory body of the Department of Science and Technology, under the Intensification of Research in High Priority Areas (IRHPA) special call on 3D Bioprinting.

Such 4D-printed parts have not been used in the clinic as yet. But such emerging technologies could pave the way for a new generation of medical devices that surgeons can deploy during surgery to heal nerves and many other tissues in coming years. They can offer benefits such as reduced complexity of surgeries, deployment by minimally-invasive procedures, and faster healing.

Scheme 2: Process showing the potential of the gel sheet to rapidly undergo shape change during surgery, forming nerve conduits for peripheral nerve repair to reduce the complexity of surgeries.

Publication link: https://onlinelibrary.wiley.com/doi/abs/10.1002/adhm.202300701