A comprehensive indigenous innovation consisting of new nozzle design, novel coating materials and a cold spray technique can now bring down costs of surface modification, repair and refurbishment, thereby aiding in the increase of life of engineering components.

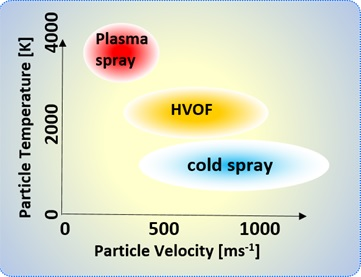

Cold spray is a type of thermal spray that coats materials and devices using high velocity, low temperature gas jet. The powder is entirely in solid state prior to impact in cold spray process unlike other thermal spray processes.

Fig.1. Classification of thermal spray techniques

Such spray processes are known to increase the lifetime of engineering components by enhancing surface properties especially where surface properties are of special importance.

Cold spray involves accelerating metallic/alloy/composite powders to very high velocities by entraining them near the convergent portion of the nozzle which creates a supersonic gas jet at exit. Powder particles remain in solid state till the impact process, which contrasts it from other thermal spray processes. Nozzle design remains a vital aspect in cold spray with various aspects contributing to final coating quality. The nozzle typically consists of a converging (Conv.) and a diverging (Div.) portion separated by a throat area.

International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous institute of Department of Science and Technology has made extensive efforts to improve nozzle design of the spray, the material as well as the coating’s performance to make the cold spray system more efficient. This one of its kind effort in India has led to a system that is more effective than those available for use till date.

The uniqueness of ARCI nozzle is that the know-how has been generated by synergistically combining design and material aspects to achieve a particular coating for a given application.

Fig.2. Schematic illustrating nozzle design

Owing to the above, ARCI offers a wide spectrum of coating materials (Cu, Al, Zn, Ag, Ti, Ta, Nb, Ni, Co) and some of their alloys with properties comparable to commercially available foreign high pressure systems. The uniqueness of the system lies in the use of air as the process gas as well as the cost efficiency owing to the development on energy efficient nozzles.

In addition to the above, novel material coatings such as High entropy alloys (HEA) have been developed for the first time ever in cold spray. Nano composites (Cu-Al2O3) and MAX phases have also been deposited. With these credentials ARCI had taken up several sponsored application development activities notable among which are development of high conductivity and oxidation resistant silver coatings on boiler tubes for BHEL Trichy wherein 3 mm thick Ag was deposited on half the circumference of a 25 mm diameter tube. Major repair and refurbishment program was taken up with Boeing India that involved deposition of thick Aluminium and alloys 2024, 6061 and 7075 and carrying out mechanical tests. ARCI has prepared to launch cold spray technology to the market with a contemporary Human Machine Interface (HMI) based automated control console ready for transfer to the Indian industry.

Fig.3.ARCI developed (a) high conductivity Ag coating (ii) Tensile specimens machined out of repaired Al alloy and (c) biocompatible coatings (right)

Publication details: https://doi.org/10.1016/j.surfcoat.2023.129839

For further information, please contact:

Dr Naveen Manhar Chavan (naveen[at]arci[dot]res[dot]in), Dr S Kumar (skumar[at]arci[dot]res[dot]in), Dr L Rama Krishna, Scientist-G and Head, Center for Engineered Coatings, ARCI, Hyderabad.