An organic solar cells consisting of a combination of an organic polymer and PCBM (an organic semiconductor) developed on steel substrates can potentially convert a steel roof into an energy-producing device with greater efficiency than those currently available in the market.

The potential of third-generation solar cell technologies lies in their integration with flexible and conformal surfaces. However, this integration requires developing new top transparent conducting electrodes as alternatives to indium tin oxide, an optoelectronic material currently in use and poses limitations because of its brittleness and as its optoelectronic efficiency varies with temperature.

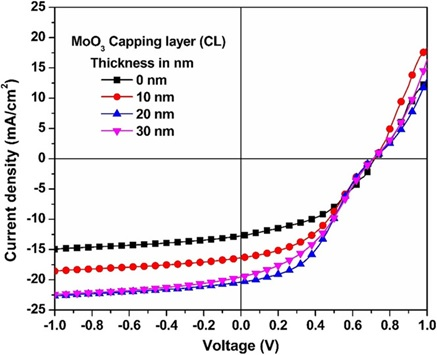

Researchers at IIT Kanpur have developed organic solar cell devices consisting of a blend of organic polymer PTB7 as a donor and PCBM as an acceptor. The devices were fabricated on opaque steel substrates with a MoO3/Au/MoO3 top electrode. The research carried out at the laboratory of Prof. Ashish Garg at IIT Kanpur demonstrated the integration of multi-layered electrodes of configuration MoO3/Au/MoO3 with the organic solar cells. It was published in the journal ‘Energy Technology’. These electrodes offer higher optical transmission as compared to only metallic electrodes. The devices with multilayer electrodes showed a clear improvement in the photovoltaic performance by 1.5 times, as compared with those obtained with single-layer top metal electrodes of gold.

Figure: Device performance of an organic solar cell device with MoO3 capping in a multi-layered electrode configuration

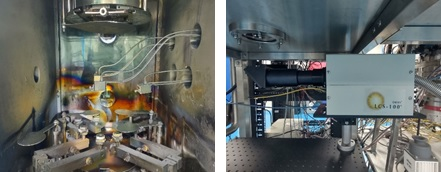

The materials and device fabrication of perovskite and organic solar cells took place in the Class 10000 clean room facility at IIT Kanpur, which was supported by funding from DST under the DST-RCUK APEX project. The facility can carry out the complete fabrication of organic and perovskite solar cells. It consists of two interconnected 4-port glove boxes maintained under a nitrogen gas environment, has the capacity for handling chemicals that are sensitive to atmospheric components, mainly moisture and oxygen, and has a vacuum annealing chamber. The glove box is integrated with a spin coater, a solar simulator, a thermal annealing setup, and a high-vacuum multi-channel thermal evaporator.

Publication Link: https://doi.org/10.1002/ente.202100689