A new piezoelectric polymer nanocomposite material developed can be useful for pressure sensing and energy harvesting applications.

Researchers from Centre for Nano and Soft Matter Sciences (CeNS), an autonomous institute of Department of Science and Technology, in collaboration with scientists from National Chemical Laboratory (CSIR-NCL), Pune have developed a security alert system based on piezoelectric polymer nanocomposite. This development was based on the finding that metal oxide nanomaterials with appropriate crystal structure and surface properties when used as fillers in a polymer composite lead to a significant enhancement in the piezoelectric response.

In today's world, energy creation and harvesting from readily available sources is crucial. Mechanical energy is a plentiful and easily accessible source that can be transformed to electrical energy through a variety of techniques, including contact electrification/triboelectric effect and piezoelectric effect. Flexible, portable, sustainable, and wearable sensors and energy harvesting devices are critical nowadays. Polymers and nanoparticles are playing a major role in present flexible electronic systems.

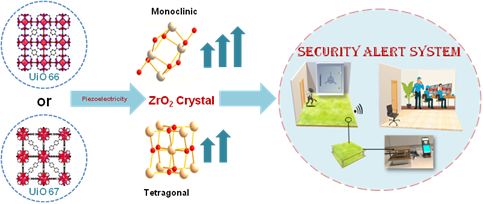

A team of scientists from Centre for Nano and Soft Matter Sciences (CeNS), Bangalore, and the National Chemical Laboratory (CSIR-NCL), Pune have successfully prepared a polymer nanocomposite material for pressure sensing and energy harvesting applications. The researchers synthesized two zirconia-based metal−organic frameworks (UiO-66 and UiO-67) which were converted to zirconia nanoparticles with exquisite control over their crystallographic phases namely monoclinic and tetragonal phases.

Polymer nanocomposite films were then fabricated by incorporating these nanoparticles with different crystal structures in to a well-known piezoelectric polymer, poly (vinylidene difluoride) (PVDF). The team of researchers evaluated the influence of varying crystal structures of zirconia nanoparticles on a piezoelectric energy-generating zirconia- PVDF composite and observed that the surface characteristics and crystal structure of the nanofillers have a significant impact in piezoelectric properties of polymer material.

Polymer nanocomposite with monoclinic zirconia nanoparticles produced from UiO-66 outperformed other derivatives and had greater piezoelectric output performance than pure polymer.

Furthermore, a laboratory-scale demonstration of a wireless, Bluetooth-based security alert system supported by an Android application was carried out, using the fabricated prototype as an energy-generating and security alert pavement unit.

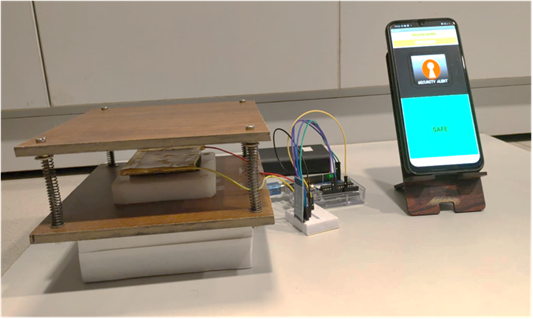

The security pavement prototype was installed in a chamber. The piezoelectric pavement generated voltage due to footsteps (mechanical to electrical energy conversion), whenever an unwanted entry took place. This activated the security system, and the Bluetooth module sent the wireless communication to the concerned screen. In the system an android phone-based app was used to demonstrate this. Apart from a touch sensor the prototype can be also used for generating electrical energy from mechanical energy input.

Prototype of piezoelectric pavement used for security alert system

This study validates the PVDF-monoclinic ZrO2 nanoparticle nanocomposites will be an excellent value addition for flexible, durable energy generation and pressure-sensing applications. This work was recently published in American Chemical Society journal ACS-Applied Nano Material. This study is part of an ongoing project “Materials for self powered energy generating and pressure sensing devices” funded by Department of Science and Technology under Inspire –faculty fellowship programme.

The methodical investigation and crystal structure modifications will undoubtedly open the door to a better understanding of the mechanism underlying the piezoelectric capabilities of polymer nanocomposites based on PVDF.

Publication details: DOI: https://doi.org/10.1021/acsanm.3c04730

For further details: Prof. B L V Prasad (Email: pl.bhagavatula[at]cens[dot]res[dot]in) or Dr. Subash C K (Email: cksubash[at]cens[dot]res[dot]in) can be contacted.