A newly developed nanocomposite coating can inhibit biofilm formation and also kill attached bacteria, thereby helping tackle growing post-operative infections, a common occurrence these days due to antibiotic resistance in bacteria.

These post-operative surgical site infections (SSIs), which according to WHO, affect 11 percent of patients in low and middle-income countries, are caused by the development of biofilms (groups of bacteria growing in formation that are highly resistant to antibiotics) on the incision site or in the soft tissue inside the site. The biofilm matrix, which may come from existing infections in the patient’s body or can be transferred from the hospital environment through potential carriers like surgical equipment, wound dressing, or bandage/surgical sutures, acts as a physical shield against antibiotics given during the operation, slowing down their penetration.

Hence, it is important to have an antibacterial coating on the surface of these materials that can act as potential sources of SSI. Conventionally antibacterial coatings containing biocides like nanosilver, nanocopper, triclosan, and chlorhexidine have been used to prevent bacterial infections. Although, Triclosan and chlorhexidine exhibit antibacterial effects towards a broad-spectrum of bacteria, they and other biocides are found to produce cytotoxicity. As a result, there is an increasing focus on developing alternative non-cytotoxic materials with antibacterial properties.

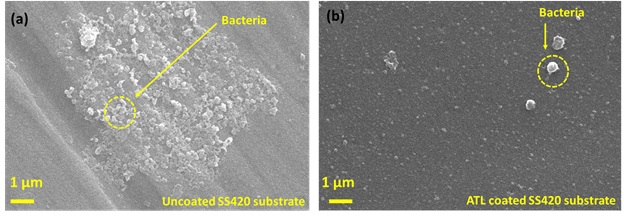

Researchers from ARCI, an autonomous institute of the Department of Science and Technology (DST), have developed a nanocomposite coating (named at ARCI as ATL) by combining water repellence and biocidal property (combinatorial approach), which exhibits both hydrophobic and biocidal behaviour. The developed coating not only inhibits biofilm formation by restricting bacterial and water adhesion but also kills attached bacteria.

ATL was deposited on different surgical sutures made of silk, nylon, and polyglactin 910 (vicryl) in addition to surgical instrument grade stainless steel 420 coupons and tested for biofilm inhibition against American Type Culture Collection (ATCC) and clinical isolate strains of proven biofilm-forming bacteria such as Pseudomonas aeruginosa, Acinetobacter baumanii, Staphylococcus aureus and Escherichia coli at Translational Health Science Technology Institute (THSTI) and LV Prasad Eye Institute (LVPEI) respectively.

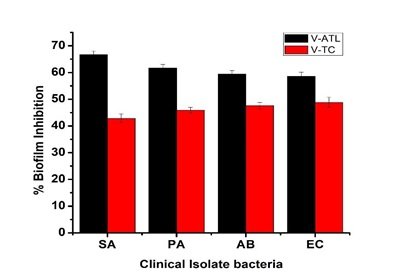

The ATL-coated vicryl sutures exhibited higher percentage biofilm inhibition when compared to commercially available triclosan-coated antibacterial sutures. Cytotoxicity of the formulation was evaluated on coated surface, and it was found that ATL coatings are non-cytotoxic. The coatings developed in the present study can be used as a non-cytotoxic alternative to the commercially available antibacterial coatings, especially for healthcare applications on surgical sutures/surgical instruments to prevent the rise of multidrug-resistant bacteria.

Figure 1. Comparison of % bacterial inhibition between ATL-coated VICRYL and triclosan (TC) coated vicryl (absorbable surgical suture) against different clinical isolate bacteria Pseudomonas aeruginosa (PA), Acinetobacter baumanii (AB), Staphylococcus aureus (SA) and Escherichia coli (EC)

Figure 2. Biofilm and bacteria morphology on (a) uncoated and (b) ATL-coated SS420 stainless steel coupons after 24 hours exposure to S. aureus clinical isolate showing biofilm inhibition and reduced number of adhered bacteria on the coated SS 420 substrate.

The above work was carried out as a Department of Biotechnology (DBT) funded multi-institutional project under Mission AMR (grant no. BT/PR31908/MED/29/1401/2019) where ARCI, Hyderabad was the Principal Investigator and Project coordinator; THSTI (Faridabad) and LVPEI (Hyderabad) were the collaborating institutes.

References:

Indian patent application titled “Biofilm inhibiting sol-gel composition for coating on substrates and process of preparing the same” R Subasri, Ramay Patra, K.R.C. Soma Raju, Susmita Chaudhuri, Prashant Garg, B. Bhaskar, Debrupa Sarkar, filed as 202111001104 dtd 11-01-2021

For more details, please contact Dr. R. Subasri (subasri[at]arci[dot]res[dot]in).