Scientists at the International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), an autonomous R&D Centre of Department of Science and Technology (DST), Govt. of India, have developed a novel metallurgical process schedule to realize Fe-P based soft magnetic alloys which could help develop them in the country for the automotive industry.

Scientists at the International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), an autonomous R&D Centre of Department of Science and Technology (DST), Govt. of India, have developed a novel metallurgical process schedule to realize Fe-P based soft magnetic alloys which could help develop them in the country for the automotive industry.

The wrought Fe-P alloys obtained under the process developed by the ARCI team have higher magnetization, lower coercivity than the expensive non-oriented Si-steel available in the market. The indigenous process developed by the team involves controlled heat treatment through phase-field, which results in the formation of nanoscale Fe3P precipitates of suitable size and distribution.

This process eliminates the operational difficulties caused by brittleness in rolling phosphorous-containing iron alloys. A very low phosphorous content added to Fe promotes a higher saturation magnetization close to 2 Tesla. The modified heat treatment ensures a favourable microstructure consisting of strain-free grains in addition to restricting the size of the nano precipitates to less than a critical size which is the width of the magnetic domain wall of iron.

Soft magnetic materials are essential and indispensable for electro-mechanical devices like motors, actuators, generators etc. Silicon-containing (typically 1 – 3 wt.%) Fe-based soft magnetic alloy steels are widely used for such applications. Consumption rate and demand for such Si-steels is increasing with each passing day, and large quantities of them are being imported.

An indigenous soft magnetic material and a substitute to the Si-steel like Fe-P alloy could save foreign exchange and also strengthen the supply chain for saving automotive industry in the country. However, Fe-P alloys cannot be processed through conventional wrought metallurgical (melting, casting, forging and rolling) route due to brittleness caused by the presence of phosphorous. Therefore, powder metallurgy (PM) based Fe-P components are quite common in industrial magnetic applications: But, such components exhibit lower magnetic properties on account of attributes induced by PM process. Hence, the industries largely depend on the expensive non-oriented (NO) Si-steel for soft magnetic applications.

The alloy developed by ARCI team is expected to be energy efficient, as the unique microstructure aids in maintaining a low coercivity in addition to enhancing the resistivity. This newly developed material not only has favourable magnetic properties for considering it as an alternative to Si-steel but is also expected to be cheaper, as phosphorous is about 30-40% cheaper than Si. More importantly, the technology being indigenous is expected to provide a strategic edge to Indian electrical steel manufacturers with the government focussing on electric vehicle (EV) as the newly developed magnetic material can prove to be crucial for EV motors.

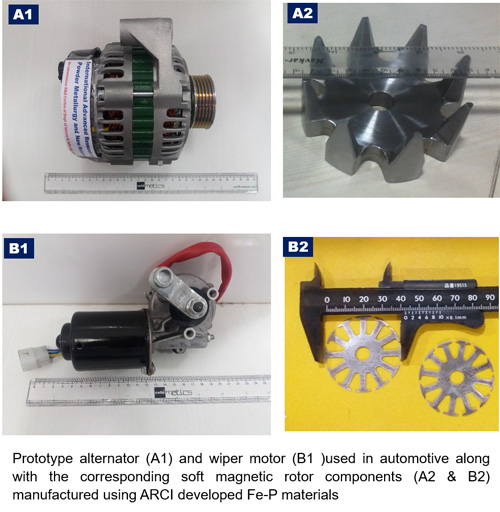

Currently, ARCI is working with an automotive component manufacturing industry to evaluate the material on an identified automotive component (Claw pole alternator). The prototypes machines have been tested under laboratory conditions using the Fe-P alloy with promising results and steps are on for completing the field trials.

For more details contact Dr D. Prabhu (dprabhu[at]arci[dot]res[dot]in)