A device that combines an efficient durable cathode catalyst and anti-freezing electrolyte fabricated for Zn-air batteries can be used as an energy source in remote areas like the Himalaya where conventional batteries may struggle due to extreme cold conditions.

In an era of escalating energy demands, efficient energy storage systems are pivotal for harnessing clean, renewable resources. Researchers are trying to develop devices with heightened energy density and reduced weight. Lithium-ion (Li-ion) batteries face constraints due to heavy cathode materials like lithium cobalt oxide and lithium iron phosphate with limiting energy density.

Metal-air batteries are emerging as promising alternatives, substituting heavy cathode materials with metals such as Li, Na, K, Mg, Al, Zn, and Fe, utilizing O2 at the air electrode to potentially enhance energy density significantly. Addressing the global demand for sustainable energy solutions, electrocatalytic techniques like overall water splitting, fuel cells, and metal-air batteries offer low carbon footprint alternatives. However, challenges persist, including low rate of energy generation and high overpotentials at complex multi-phase interfaces.

To overcome these challenges there is a need to develop high-efficiency heterogeneous catalysts. Multifunctional catalysts capable of accelerating the ORR (oxygen reduction reaction), OER (oxygen evolution reaction), HER (hydrogen evolution reaction) simultaneously are particularly promising as they promise reduced material usage, simplified designs, enhanced energy utilization, and improved device integration.

M/NC catalysts featuring atomically dispersed transition metals (M = Fe, Co, Ni) within nitrogen-doped carbon hosts have garnered significant interest. Renowned for their excellent electrical conductivity, abundant 3d electron configuration, and versatile M-Nx catalytic sites, these catalysts demonstrate enhanced intrinsic activity through electron density redistribution to nearby defective carbon atoms.

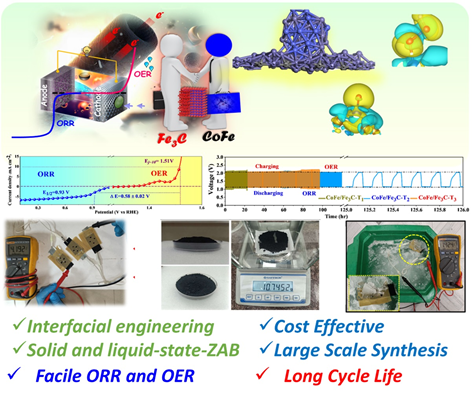

A DST Inspire Faculty Fellow Dr. Aniruddha Kundu and his team from CSIR-CMERI, Durgapur synthesised a cathode material by integrating CoFe alloy and Fe3C nanoparticles using an in-situ growth technique. The result is a simple integrated heterostructure of biphasic Co0.7Fe0.3/Fe3C (CoFe alloy/iron carbide) embedded on in situ grown N-doped carbon sheets.

The CoFe/Fe3C alloy/carbide hybrid structure enhances the durability and showed catalytic performance as a cathode. The material demonstrates remarkable efficacy in both liquid and solid-state zinc-air batteries, even under sub-zero temperatures, thereby showcasing its potential for practical electrochemical applications.

A liquid-state ZAB was fabricated using as-designed Co0.7Fe0.3/Fe3C as air-electrode, which is capable of simultaneously catalyzing ORR and OER; Zn foil as anode and 6 M KOH as an electrolyte. A transparent, flexible, and stable PVA-CMC based gel electrolyte was designed. The gel film was submerged in a concentrated 10 M KOH+0.2 M Zn(OAc)2 solution for 24 hours at room temperature before assembling in solid-state Zn-air battery (ZAB). For flexible ZAB except PVA-CMC gel electrolyte all conditions were like the liquid ZAB.

In their work published in the journal Advanced Functional Materials, the researchers have created a devise by integrating the innovations, opening up significant possibilities for practical applications. The portable, flexible, and lightweight nature of our device makes it an excellent choice for a wide range of users. It can provide reliable energy solutions not only to everyday consumers but also to military and defense personnel operating in remote and challenging environments.

By enabling energy independence in harsh climates and remote locations, the technology represents a promising advancement towards sustainable and resilient energy solutions accessible to all.

Publication link: https://doi.org /10.1002/adfm.202407078