Indian researchers have developed superhydrophobic coatings that can improve stainless steel's corrosion resistance, making it usable in marine applications, pipelines, power generation, and nuclear sectors.

Superhydrophobic or ultralow wetting surfaces with self-cleaning properties have been a subject matter of intense research for past couple of decades due to their high industrial relevance. When a drop of water is placed on a solid surface, it will spread on the surface based on the intermolecular interactions between the solid and the liquid. The wettability of a surface is measured by its water contact angle. Superhydrophobic (SHP) surfaces are those with water contact angle greater than 150 º and sliding angles less than 5 degrees. The conventional method of generating a superhydrophobic surface is by deposition of a polymer or sol-gel formulation in which nanoparticles are dispersed. This method helps to simultaneously make a physical as well as chemical modification of the surface, thereby generating superhydrophobic coatings in a single step. However, there are few shortcomings of such superhydrophobic coatings in their durability, mechanical properties, and adhesion with the substrate.

A team of researchers from the International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), an autonomous institute of the Department of Science & Technology (DST), Govt. of India, investigated the durability of their developed superhydrophobic (SHP) coatings on a stainless steel SS 304 to improve its corrosion resistance. SS 304 is used in industrial applications such as marine, machinery, electronic parts, piping, power, nuclear sectors due to its excellent workability and cost-effectiveness.

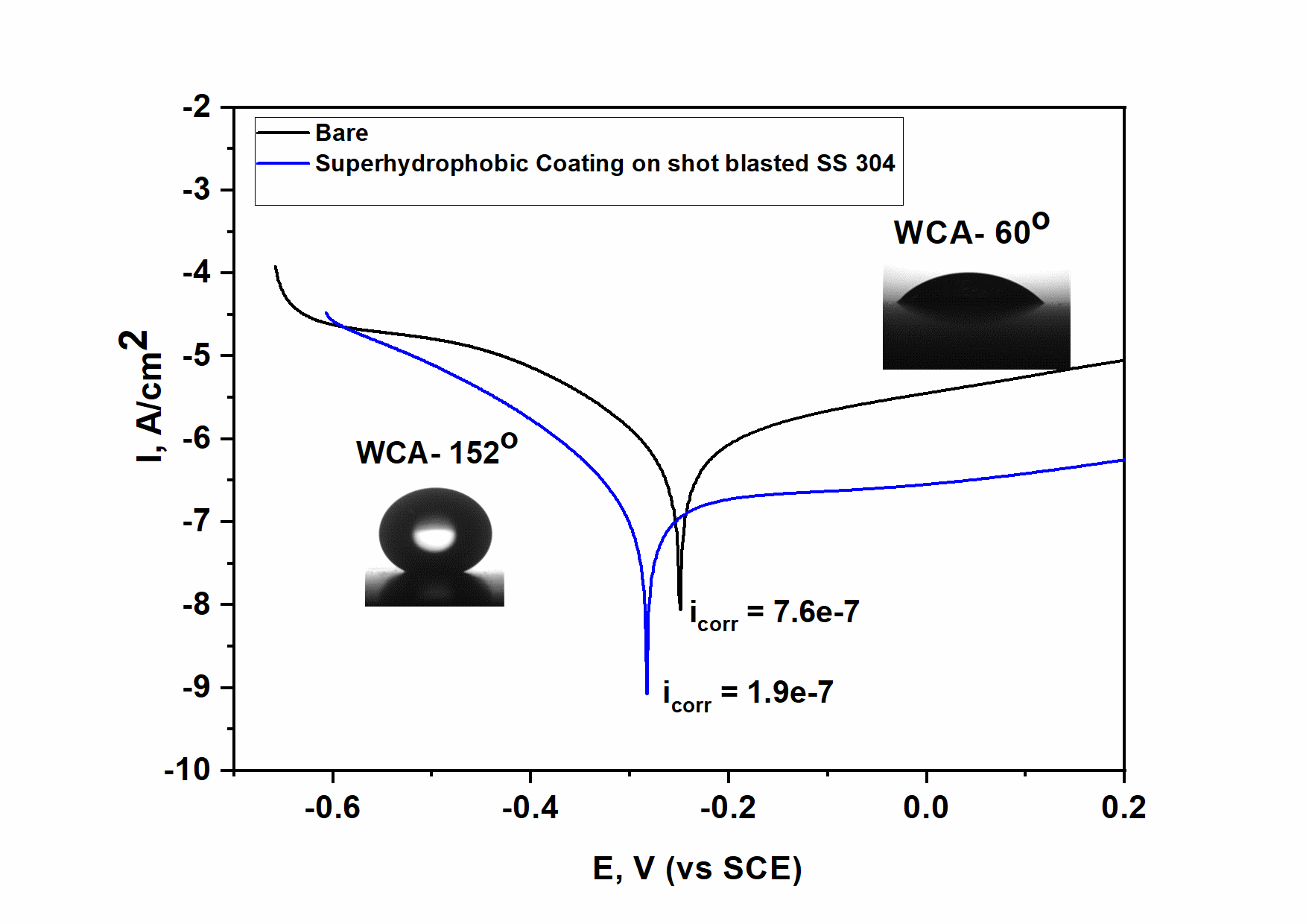

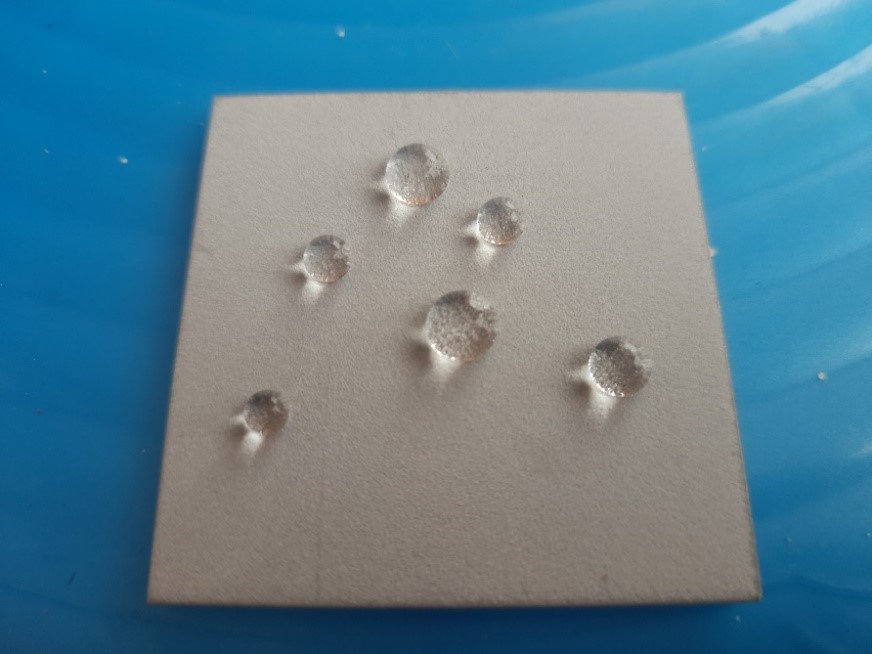

The team explored shot blasting, a technique that improves the adhesion of coatings on a substrate surface, along with nanocomposite superhydrophobic sols for the generation of adherent and durable superhydrophobic surfaces on SS 304 substrates. With these surface modifications, the water contact angle increased from 84° for the bare substrate to 160° for the SHP coated substrate. The stability of coatings was evaluated by measurements of abrasion resistance, weather resistance, and corrosion resistance.

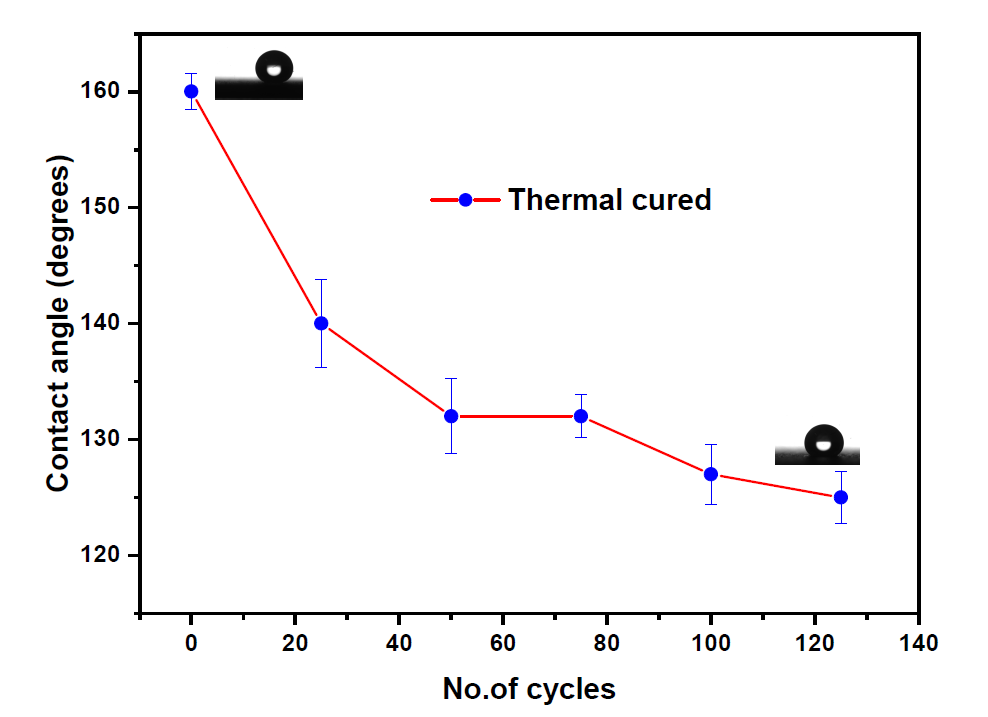

It was observed that the developed coatings were able to withstand 100 cycles of abrasion testing. These coatings also exhibited superior corrosion resistance, which can help overcome the problems encountered by stainless steel 304 in harsh and contaminated environments such as marine and gas pipelines, including surface aging and corrosion.

WCA of crock meter abraded superhydrophobic coatings

Potentiodynamic polarization data for bare and superhydrophobic coated shot-blasted SS 304

Water droplets (3-5 µl) on superhydrophobic coated SS 304 (50 mm x 50 mm)

For more details, contact K Srinivasa Rao and Dr. R Subasri (subasri[at]arci[dot]res[dot]in) Centre for Sol-gel Coatings, ARCI.