Mr Santosh Semwal, a 32 year-old resident of Matli in Uttar Kashi runs an enterprise which produces precast concrete building products including RCC plank and joist for flat slab construction, RCC door window frames, concrete flooring tiles and paver blocks.

The enterprise supplies precast concrete products for several buildings. The Public Works Department in Uttarkashi have also shown interest and asked for the technical details of the products. Additionally, individual house builders are also showing interest in the products. The entrepreneur has now procured a pigment mixing machine and moulds for paver blocks at his own expense to widen the range of products.

The materials provide for safe disaster construction in the mountain eco-systems and are also eco-friendly, culturally responsive. They can also contribute to the growth of the local economy through new green jobs, all of which DST’s TIME-LEARN initiative’s aim.

The project introduced construction technology that adds value to local resources, built skills across the construction value chain and set up local production units for continued supply of resource efficient and low carbon building materials to develop culturally and climatically conducive models of housing and village public buildings.

This enterprise has been supported by a project titled ‘Delivery of Eco-friendly Multi-Hazard Resistant Construction Technologies and Habitat Solutions in Mountain States’ under TIME-LEARN programme, supported by SEED Division, DST along with HESCO, WII and Forest Research Institute (FRI) Dehradun. The project demonstrated building material technology packages in three key clusters, namely, Concrete based, Local timber-based, local soil-based each of which is amenable for local production through an enterprise model.

The project aims to upgrade the skills of traditional artisans and enable their transition to S&T based production organizations and to develop new technologies for improvement and diversification of the local economy and use local resources and people.

This programme--Technology Intervention for Mountain Ecosystems (TIME), Livelihood Enhancement through Action Research & Networking (LEARN), is a mechanism developed for promoting Science and Technology (S&T) by involving premier S&T institutions, field groups and voluntary organizations to develop and implement innovative solutions for mountain-specific problems and challenges in the North-Western Himalayas in the states of Uttarakhand, Himachal Pradesh and Jammu and Kashmir.

The concept was developed by Science for Equity, Empowerment & Development (SEED) Division, Department of Science and Technology, Government of India along with Himalaya Environmental Studies and Conservation Organization (HESCO) and Wildlife Institute of India (WII), Dehradun.

The microenterprise underlining the concept has been set up jointly with support from the project and contribution by the entrepreneur. The project contributed in terms of production equipment-tools, and technical support through training of the entrepreneur and his production team consisting of a supervisor, machine operator, masons and semi-skilled labourers. The entrepreneur provided the land, water and electricity connection and essential infrastructure like production shed, storage room and curing tank. Currently, marketing and communication support is also being extended to the enterprise for strengthening its position in the regional market.

Initiated with an investment of in fixed assets to the tune of INR 700,000 Semwal ‘s enterprise has created a supply node for precast RCC building elements which provides an alternative to conventional construction using RCC and bricks, which provides a cheaper and long-lasting alternative to timber door-window frames. It offers high quality products, which provides an alternative for faster and cost-competitive construction and by virtue of its location is in a good position to cater to the Uttarkashi market and introduce the validated products in government works.

The prevailing construction in the mountainous regions of Uttarkashi depends on the material which is transported over large distances – particularly cement and burnt clay bricks. Thus, the transport involved adds to the energy consumption and carbon footprint of construction. In addition, RCC slab construction is routinely of poor quality due to lack of understanding of masons which leads to resource inefficiency. The new precast products ensure high quality and durability and lower resource intensity due to reduction in concrete and steel quantities as compared to RCC slab.

The enterprise also helps direct and indirect employment generation through local manpower used in production and ensures a greater contribution to the local economy by bringing value-added products to the regional market.

Small scale precast products such as those produced by these enterprises are a promising alternative to conventional construction material because of higher quality and durability as well as the relative ease of transport. There is no source of such products in the Uttarkashi market, apart from paver blocks which are becoming quite common for external applications.

Hence, Mr Semwal’s enterprise fills in the gap with new products which are both tested and validated by leading research and certification agencies which can also be used for governmental projects, such as housing and institutional buildings and private projects like houses and home-stays. Additionally, there is tremendous scope for expansion into other high-volume materials like concrete cover (for reinforcement) blocks.

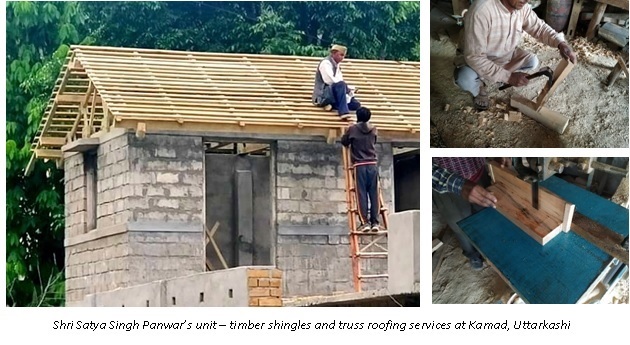

A village based carpenter’s unit also has been set up that based on local timber which provides comprehensive production, treatment and roof installation services using Chir pine shingles and timber understructure as an alternative to slate stones and GI sheet roofs.

There is also a local Soil Based enterprise in which a women’s unit moves from village to village to produce and supply Compressed Stabilized Earth Blocks for wall construction masonry as a replacement to clay fired bricks.

Besides, building STI capacities of mountain communities specifically women, artisans and engaging youth in social enterprises sector the project is also in line with achieving SDGs 1, 4, 5, 10 on reduced poverty, gender equality, education to all, decent jobs and reduced inequalities.