Scientists have found a clue to explain the fingering instability in viscoelastic fluids —a phenomenon in the flow of materials like corn starch in confined environments that resemble porous media. The new explanation of fingering instability can help in the effective displacement of slurries with maximum efficiency.

A simple ingredient like corn starch, a common ingredient used in cooking as a thickening agent in soups and gravies, behaves like a solid when slurry is punched. Likewise, when under impact, the lightweight kevlar vests can thicken and are best used as body armours. That is, both these materials solidify when under high stresses.

Researchers at the Raman Research Institute (RRI), an autonomous institute funded by the Department of Science and Technology (DST), have offered some scientific clues about a novel instability called fingering instability seen during the transport of shear thickening corn starch slurry.

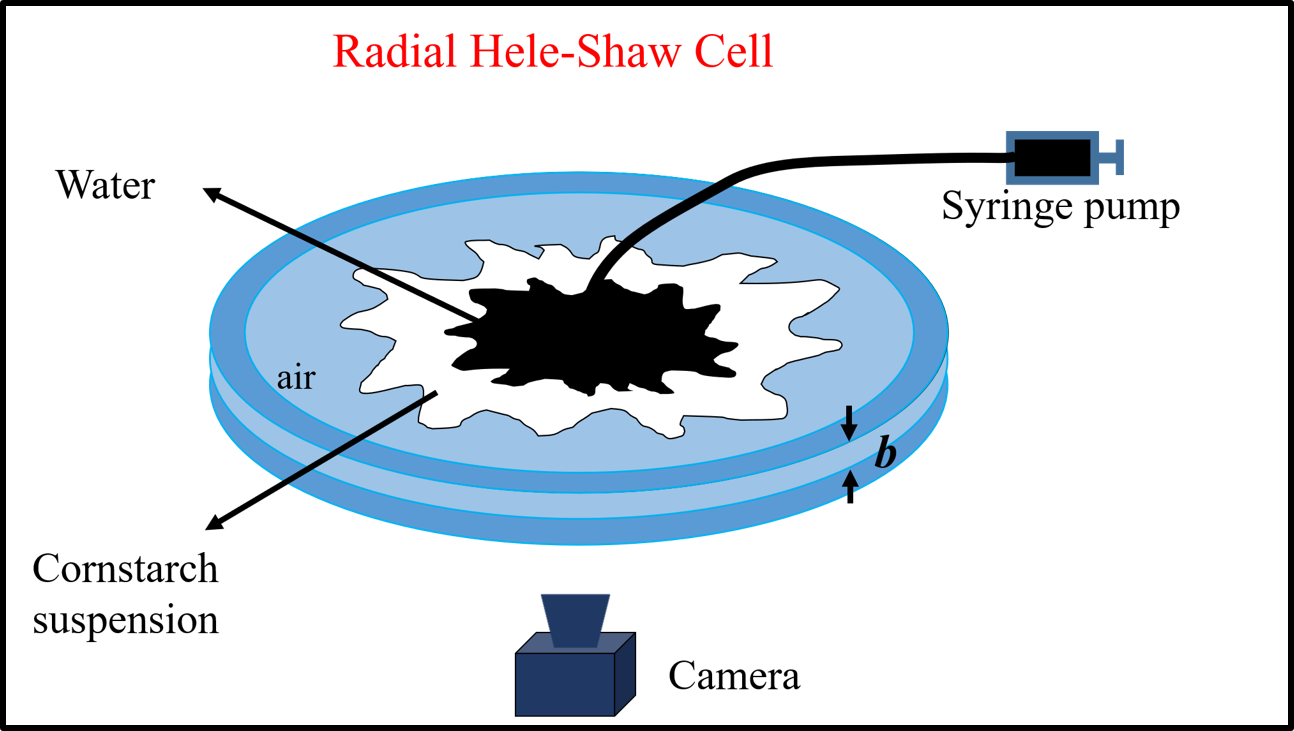

The RRI researchers have studied and described how corn starch slurry, in a shear-jamming regime, behaves when pushed out by water or mineral oil. In the experiment, researchers filled a quasi-two-dimensional geometry, called a Hele-Shaw cell, with corn starch slurry. Water was then injected to displace the slurry at a controlled flow rate. They observed patterns and fingers developing on the interface, as the water pushed the corn starch slurry. The same experiment was repeated using mineral oil and similar observations and development of finger structures were noticed.

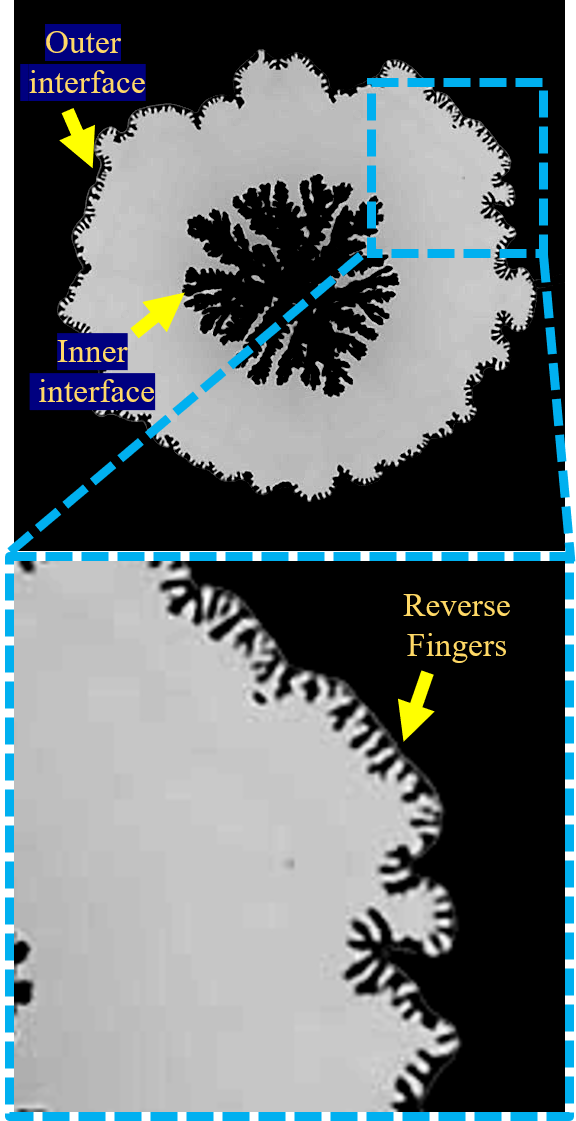

The experimentalists observed that the inner interface, due to the interaction between water (or mineral oil) and corn starch, resulted in elongated structures (known as fingering instabilities) growing outwards. These fingers could measure up to 10cm in length and continued to grow with the constant supply of water (or mineral oil). Simultaneously, the interaction between corn starch and air on the outer-interface led to the development of additional fingering instabilities that grew in the reverse direction, some as long as 1.7 cm.

“Surprisingly, these reverse fingers were seen growing and later withdrawing completely, all within a few seconds,” said Prof. Ranjini Bandyopadhyay, whose lab in the Soft and Condensed Matter Physics at RRI is working on deciphering complex fluids. Results discussed in the paper titled ‘Emergence of transient reverse fingers during radial displacement of a shear-thickening fluid’ were published recently in the journal ‘Coll. Surf A: Physicochemical and Engineering Aspects’.

When injected with a high flow rate, the research team found that the water or mineral oil sets the corn starch particles in motion. The corn starch particles come into close contact with one another, resulting in the development of a system-spanning frictional force chain network. This network causes an increase in the viscosity of the slurry, and the system enters into a shear-jamming regime. The scientists noted that thicker corn starch slurry produced stronger force chain networks, thus producing more pronounced reverse fingers.

“High shear causes corn starch particles to roll over each other, leading to shear jamming in the suspension while pushing particles into the liquid-air boundary. Particles at the boundary are then subjected to a confining pressure caused by the surface tension of the solvent. This surface tension-driven restoring force drives the formation of the observed reverse fingers.” added Vaibhav Raj Singh Parmar, another co-author of the paper.

This research provides new insights into how viscoelastic materials like corn starch behave under stress and hence can help control the phenomenon called fingering instability. The knowledge of these novel fingering instabilities can be applied in a variety of scenarios, such as in slurry displacement.

Publication link: https://doi.org/10.48550/arXiv.2209.01614