Indian Scientists have developed an environment-friendly process for improving the lasting of a material in the face of corrosion (corrosion-fatigue life) of high strength aerospace Aluminium alloys that make aerospace structures sufficiently light.

Aluminum alloys are used in aerospace, automobile, and marine applications due to their low density and high specific strength (strength-to-weight ratio). Among various aluminum alloys, heat treatable wrought alloy compositions possess high mechanical strength and are commonly preferred by the aerospace industry. The aerospace components of these aluminum alloys, including landing gear, wing spar, fuselage, skins, pressure cabins, and so on, are expected to possess high fatigue life and corrosion resistance.

Though Aluminum alloys' corrosion resistance is significantly enhanced by depositing harder alumina (Al2O3) coating through anodic-oxidation-based processes, these processes employ concentrated acids as their electrolyte, leading to emission of toxic fumes that are non-eco-friendly processes. This challenge calls for a multi-functional environment-friendly coating, which can protect the aluminum alloys from corrosion and fatigue damages.

Scientists at the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous institute of the Department of Science & Technology (DST), Govt. of India, found that Aluminum alloys wear and corrosion resistance are significantly enhanced by depositing harder alumina (Al2O3) coating through anodic-oxidation-based processes --- anodizing, hard anodizing, and micro-arc oxidation (MAO).

While the MAO process employs a dilute concentration of alkaline electrolyte wherein toxic fume liberation is absent, spent electrolyte disposal does not attract any environmental regulations. Therefore MAO is regarded as an eco-friendly process. The Alumina (Al2O3) coatings deposited through the MAO technique possess high hardness (1000-1900 HV), excellent wear, and corrosion resistance as compared to identically thick hard-anodized (HA) coatings (300-500 HV). The work has already been published in the journals like International Journal of Fatigue recently, and patents were granted in Indian and abroad.

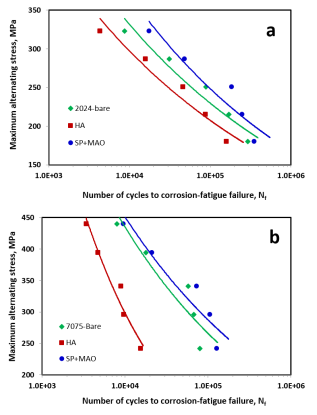

A duplex treatment developed at ARCI involving a shot peening (bombardment of a component surface with spherical balls of few hundreds of micro meter size, travelling at specific kinetic energy) operations before the MAO coating (SP+MAO) depositions has led to the significant enhancement in fatigue life of Al alloys by ten times without affecting the essential wear and corrosion resistance of the coating.

The presence of beneficial compressive residual stresses beneath the substrate-coating interface delays the crack propagation and results in superior fatigue life, which can be useful for light-weighting of aerospace structures.

Fig. Corrosion-fatigue performance of (a) 2024-T3 and (b) 7075-T6 Al alloys under different

material conditions. SP+MAO coatings demonstrate superior corrosion-fatigue life

References:

- Process for forming coatings on metallic bodies and an apparatus for carrying out the process LR Krishna, AV Rybalko, G Sundararajan, US Patent 6,893,551

- Process for continuous coating deposition and an apparatus for carrying out the process, LR Krishna, NP Wasekar, G Sundararajan, US Patent 8,486,237

- Corrosion-Fatigue Performance of Hard Anodized and MAO-Coated 2024-T3 and 7075-T6 Aerospace Al Alloys, Y Madhavi, L Rama Krishna, N Narasaiah, Transactions of the Indian Institute of Metals, 74, (2021) 2231–2243

- Corrosion-fatigue behavior of micro-arc oxidation coated 6061-T6 Al alloy, Y Madhavi, LR Krishna, N Narasaiah, International Journal of Fatigue 142, (2021) 105965

For more details, Dr. L Rama Krishna (lrama[at]arci[dot]res[dot]in), Centre for Engineered Coatings, ARCI, can be contacted.