A slew of COVID preventive technologies ranging from antiviral coating for PPEs to masks offering different levels of protection, compostable antiviral hand gloves as well as nano-fabric respirators could be effective in the third wave of the pandemic.

The technologies supported by the Nano Mission implemented by the Department of Science & Technology (DST) have been scaled up for use in COVID prevention.

Prof. Ashwini Agrawal & Prof. Manjeet Jassal from IIT-Delhi have developed the antiviral coating in the form of a sprayable liquid for PPEs and surfaces. Chemically it constitutes N9 blue nanosilver, and its nanocomposites and the transparent coating can act as a protective for all kinds of porous and non-porous surfaces, such as masks, coveralls, metal knobs and railings, plastic buttons, bags and sheets, wood products, glass surfaces, etc. They have scaled up the technology through tie-up with IIT Delhi startups-- Incipient Materials and Nanoclean Global.

The product is a highly stable antiviral formulation based on Aqua silver technology and showed 99.9% reduction of viral burden in less than 30 minutes of contact and long-lasting protection for over 45-60 days. Antiviral testing carried out at national and international labs showed excellent activity (98-99%) against viruses like Felina Corona virus, HINI, HIN2, and MS2 in 2 h of contact time. An Indian Patent and a trademark has been filed in Dec 2020, and further product prototypes have been prepared for Antiviral Masks and all-in-one Surface Protectant.

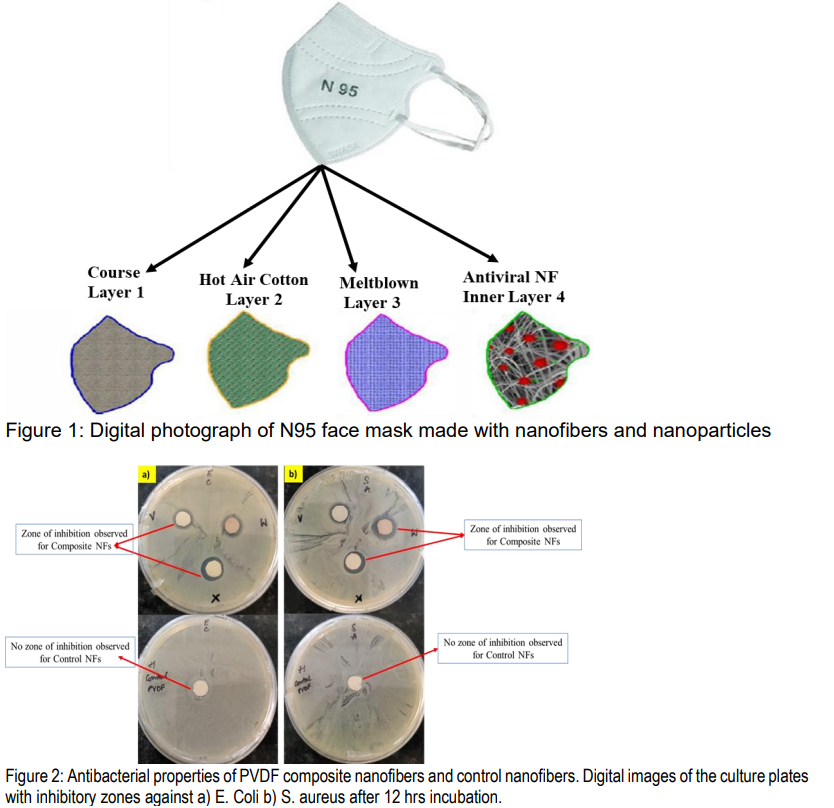

Scalable and reusable N95 and N99 masks with enhanced antiviral and antibacterial properties have been developed by Professor Sri Sivakumara from IIT-Kanpur in collaboration with E Spin Nanotech, Kanpur, a start-up company incubated from Nanoscience Center, IIT Kanpur, as industrial partner. The group has fabricated an N95 face mask made with electrospun Polyacrylonitrile (PAN) nanofibers and ZnO nanoparticles showing antiviral and antibacterial properties. The mask is reusable after washing with water and has good breathing compatibility. Further, the process developed is scalable.

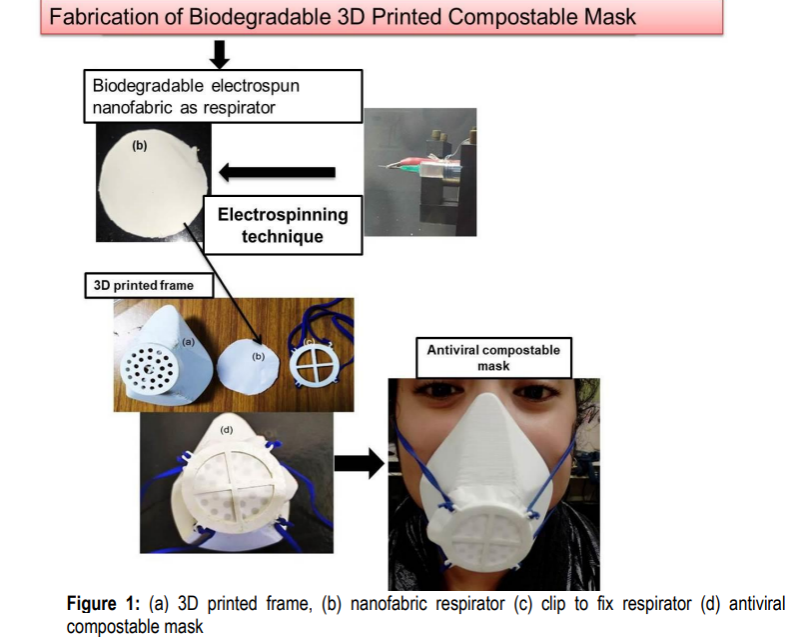

Professor Vimal Katiyar from Department of Chemical Engineering, IIT-Guwahati, in collaboration with several industrial partners--- Aditya Birla Science and Technology, GLOCAL3D Labs Private Limited, AYAPPA Nagar, Tiruchirappalli, Tamil Nadu, and Biocograd Technologies Nalbari, Assam, India, a start-up in Assam has developed a series of products that can effectively counter the virus. They include antiviral and compostable - facemask, Moisturizer, and Hand Gloves, Antiviral Compostable Mask 3D printed bio-degradable polymer-based facemask, and nano-fabric respirators via electrospinning technique.

Additionally, antiviral biopolymer molecules have been electro sprayed to incorporate functionalities into the nano-fabric respirators converting them into antiviral masks. The compostable/biodegradable antiviral facemasks were now promoting environmental sustainability and tackling the problem of facemask disposability by alleviating the problem of one-time use of masks.

The reusable and washable nano-fabric respirators were found to have more than 97% efficacy rate against viruses, non-toxic and compostable.

With due help from collaborators, antiviral biopolymer molecule has been added into conventional cream manufacturing process which has effectively converted into an anti-viral cream. This will not only act as a moisturizer for the skin but is also expected to give protection from viruses to reduce the inter-personal transmission. It is non-toxic and compostable.

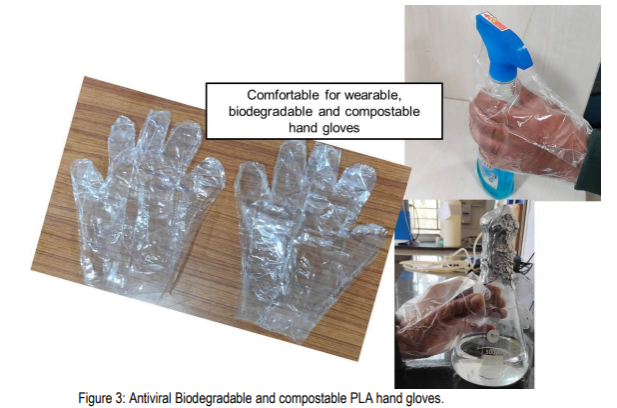

Apart from this, compostable films have been developed through unique anti-viral masterbatches having antiviral activity. This film has been used to make hand gloves. The gloves are designed for everyday use as well as for precise laboratory work with protective function that will be very effective at the industrial level and can also be used by surgeons as well as common people to ensure that their hands are free of virus. It is non-toxic and compostable.