A new method of developing alloys produces the best combination of yield strength and fracture strain. The method developed by scientists of International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI) involves a two stage process of fabrication.

Austenitic steels are among the promising structural materials used in power plants and reactors owing to excellent creep, corrosion and oxidation resistance compared to ferritic / ferritic–martensitic steels. They can withstand high temperatures, large stress, chemically reactive environments and intense neutron radiation fields, but suffer from inferior tensile strength and stress corrosion resistance at higher temperatures. Besides, one of the major concerns for its effective utilization in advanced nuclear power reactors is severe swelling due to irradiation which can be reduced by introducing stable nano oxide particles into austenite matrix. The high energy ball milling method used to disperse oxide particles in metal matrix invariably leads to powder sticking to the milling media and thus decreasing the milled powder yield. Using carbon containing process control agents (PCA) such as stearic acid results in carbon pickup which will promote coarsening of oxide particles.

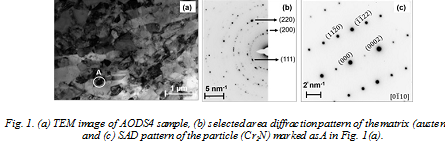

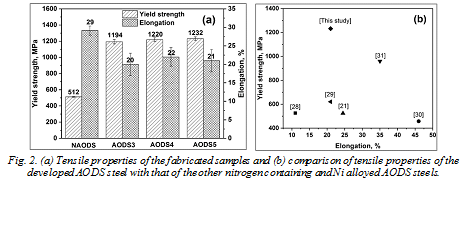

A two stage ball milling without the addition of any carbon based PCA has been employed by scientist of ARCI, an autonomos institute of the Department of Science and Technology. The first stage milling is aimed at dispersing the oxide particles into the ferrite matrix, which is the starting powder microstructure and the second stage milling is to transform the oxide dispersion strengthened (ODS) ferritic steel into austenitic ODS (AODS) steel by the addition of Nickel (Ni).

Nitrogen gas was used as PCA in both the stages of milling to improve the milled powder yield. The alloy developed in this method was found to have one of the best combinations of yield strength and fracture strain. The research published in [Mater. Sci. Eng. A 814 (2021) 141192] shows great promise for next generation of ultra high strength steels for high temperature applications.

For more details contact Dr. S.B. Chandrasekhar, Scientist- ‘F’, Email: chandru[at]arci[dot]res[dot]in