A new material designed with unique marigold-like carbon nano-structures and demonstrating highest efficiency so far of converting solar to heat energy, can transform the solar-thermal energy market in India targeting towards net zero carbon emission.

For most of human history, fossil fuels have served our thermal energy requirements with adverse effects on environment and biodiversity and increasing greenhouse gas emissions. Though off late humans have learned to harness light directly from the sun and converting it thermal energy, only a miniscule percentage of the total heat energy the sun radiates has been utilised.

Now, a new material designed at the Indian Institute of Bombay (IIT Bombay) has made a breakthrough in the amount of heat that can be absorbed and stored. Called nanostructured hard-carbon florets or NCF in short, the material has shown the highest solar-thermal conversion efficiency so far—87%. It absorbs more than 97% of the ultraviolet, visible and infrared components of sunlight and converts this efficiently into thermal energy that can be effectively transferred to either air or water for practical applications. The researchers involved in the study demonstrated that NCFs heats the air from room temperature to 60 degree Celsius and can thereby provide smoke-free space-heating solutions.

“This is particularly relevant for heating spaces located in cold climatic conditions that receive abundant sunshine such as Leh and Ladakh” said Prof. C. Subramaniam.

Solar thermal convertors, like those present in solar water heaters, are already in use in many places around the world, but most of them are expensive, bulky and potentially harmful to the environment. “Conventional coatings and materials for solar-thermal conversion are based on chromium (Cr) or nickel (Ni) films. While anodised chromium is a heavy metal and toxic to the environment, both Cr and Ni-films exhibit solar-thermal conversion efficiencies ranging between 60-70%. In fact, the best commercial ones in the market operate at 70% solar-thermal conversion efficiencies,” highlighted Dr. Ananya Sah, the lead author of the study published in ACS Applied Materials & Interfaces and npj Clean Water that developed the NCF. NCFs on the other hand, made primarily of carbon, are inexpensive to produce, environment-friendly and easy to use.

For efficient conversion of the solar thermal energy into usable heat, a material needs to have two important but contrasting characteristics. Firstly, the ability to successfully convert a large portion of the incoming packets of light or photons into heat - a process called photon thermalization. Secondly, it should have the ability to retain that heat without loss due to thermal conductivity and radiation. When incoming photons strike a material they cause the atoms of the material to oscillate. These oscillations, called phonons, then travel through the material spreading the heat throughout the material. Materials with higher phonon thermal conductivity spread the heat faster, eventually losing a majority of the heat falling on the material. Hence a good heat absorber must have high photon thermalization and low phonon thermal conductivity. NCFs tick both these boxes.

The structure of the nanoparticles of NCF composed of interconnected tiny cones of carbon is unique in that it allows for both strong phonon activation when photons strike it and low phonon thermal conductivity. “NCF has ordered structure in short-range (shorter lengths) and disordered structure in long-range (longer distances). So, when light energy is absorbed by NCF, this short-range ordering causes strong phonon activation (oscillations in the ordered lattice). Anything that has strong phonons should also help in conducting the energy away. However, in NCF, the long-range disorder acts to scatter these phonon-waves. Therefore, the phonon thermal conductivity is low,” explains Prof. Subramaninam.

Apart from its remarkable efficiency of converting sunlight into heat, another advantage of NCFs lies in their processability. Using a technique called chemical vapour deposition; carbon is deposited onto a substrate of amorphous dendritic fibrous nanosilica (DFNS) to form the NCF. The materials are readily available and the technique is easily scalable, making large-scale manufacturing commercially inexpensive. Once manufactured, NCFs can be spray-painted onto almost any surface, similar to powder coating a surface, reducing the cost of application and maintenance.

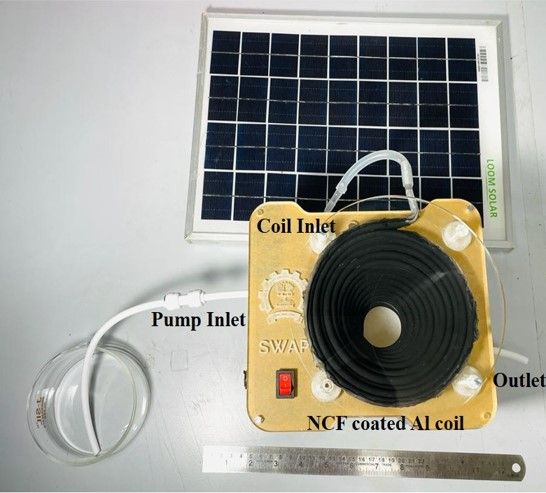

The researchers showed that hollow copper tubes coated with NCFs can heat air flown through them to over 346 Kelvin. They have also demonstrated its ability to convert water into vapour for purification with an efficiency of 186% (apart from NCF heat, it is also absorbing radiative heat from atmosphere) -the highest ever recorded. “Outperforming all other competition for efficient conversion of the sun’s energy, one metre square of NCF coatings converts 5 litres of water in an hour, that is at least 5 times better that commercial solar stills. Besides, we have also demonstrated that the heat generated by NCF can be used to heat water to 80 oC, resulting in its effective disinfection from common pathogens. Such compact 1 m2 units can provide disinfected water at 42 liter per day and relies solely on sunlight for its operation,” said Prof. C. Subramaniam..

The study supported by the SwarnaJayanti Fellowship and Materials for Energy storage programs of the Climate Change & Clean Energy (C³E) Division, Department of Science and Technology (DST) can aid in the global transition to sustainable energy sources. The team has already begun the process of commercialising the product by setting up a company at the Society for Innovation and Entrepreneurship (SINE) at IIT Bombay. The company will focus on scaling up the manufacturing of NCFs and developing NCF-based devices required for water heating and space-heating.

Links to the published papers