Amartya Mukhopadhyay, Professor at the Department of Metallurgical Engineering and Materials Science, IIT Bombay, a Swarnajayanti fellowship awardee of 2020-21, will be developing next-generation sustainable alkali metal-ion batteries that are high-performance and safe for both health and environment, using principles of classical metallurgy and materials.

Marginal improvements in the cell capacity have taken place over the last two decades for Li-ion battery systems. This is because while some modifications have been done to the cathode side, the anode side has been left almost untouched – it has largely remained graphitic carbon, which reversibly stores Li-ions via an intercalation mechanism and possesses a limited capacity.

However, potential ‘alloying-reaction’ based anode materials suffer from stress-induced degradation during electrochemical cycling, which, when used, cause rapid capacity fade with charge/discharge cycles. Hence, successful usage of the higher capacity and ‘safer’ ‘alloying-reaction’ based anode materials is imperative towards the true development of next-generation Li-ion batteries and also widespread development of Na-ion batteries, for which graphitic carbon cannot be used since it does not intercalate Na-ions.

Prof. Mukhopadhyay, who won the Swarnajayanti fellowship instituted by the Department of Science & Technology, Govt. of India, and his group focuses on addressing the problems associated with structural changes and stress-induced degradation of electrode materials by tuning the materials themselves in terms of compositions, inherent structural aspects, and properties, to render them mechanically stronger and to suppress undesirable structural transformations from occurring during electrochemical Li-ion or Na-ion insertion or removal.

In the case of ‘alloying-reaction’ based anode materials, this will involve alloy designs, invoking the principles associated with solution/precipitation strengthening and multi-component systems; which have mostly neither been thought about by the battery community earlier and nor by the metallurgical or materials community in terms of extending the concepts towards application in battery materials. Unlike the approaches adopted to date, these will attack the very root causes of the problems.

The ongoing and planned research not only targets the ‘alloying-reaction’ based anode materials but also the next-generation ‘layered’ transition metal oxide-based cathode materials for Li-ion/Na-ion batteries; all of which suffer from some instabilities at different states-of-charges and charge/discharge cycles.

His research will also address energy density (i.e., energy stored per unit mass/volume), power density (i.e., faster uptake/delivery of stored energy), cycle life, and safety of the advanced batteries to be used in electric vehicles and for storage of harvested energy based on solar power generation. Outcomes of such research are already contributing to and are more than expected to lead to the development of next-generation Li-ion and beyond Li-ion battery systems that can potentially help revolutionize the EVs and usage of renewable sources towards a ‘green’ future.

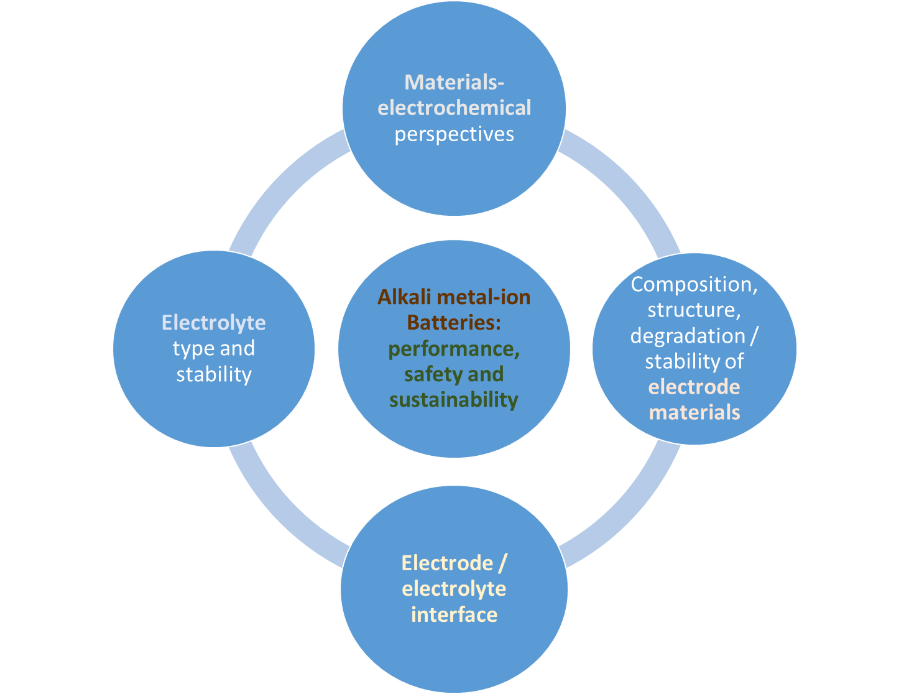

Figure: Depicting battery research in Prof Mukhopadhyay’s laboratory at IIT Bombay.

For more details, Amartya Mukhopadhyay (amartya_mukhopadhyay[at]iitb[dot]ac[dot]in) can be contacted.