Scientists have developed a new procedure to construct a covalent framework with ultrahigh surface area and devised strategies to enhance the area of adsorbent surface to make carbon capture more efficient.

An upsurge in atmospheric CO2 concentration is mostly the outcome of rapid industrial advancement and human activities, which in turn amplifies the natural greenhouse effect and raises the earth's temperature. Scientists have been trying different methods of Carbon dioxide capture to resolve this challenge. Highly ordered and robust adsorbents are extremely relevant in this context and Covalent Organic Framework (COF) materials have significantly burgeoned their scope in diverse applications. Covalently-linked organic frameworks (COFs) are well-known functional moieties for their high surface area, and thus surface adsorption can also be accelerated with higher surface area.

Scientists at the Institute of Advanced Study in Science and Technology (IASST), an autonomous institution of the Government of India, Department of Science & Technology developed a simple hydrothermal procedure to construct a covalent framework with ultrahigh surface area that shows active adsorption of carbon dioxide (CO2) at variable temperature ranges.

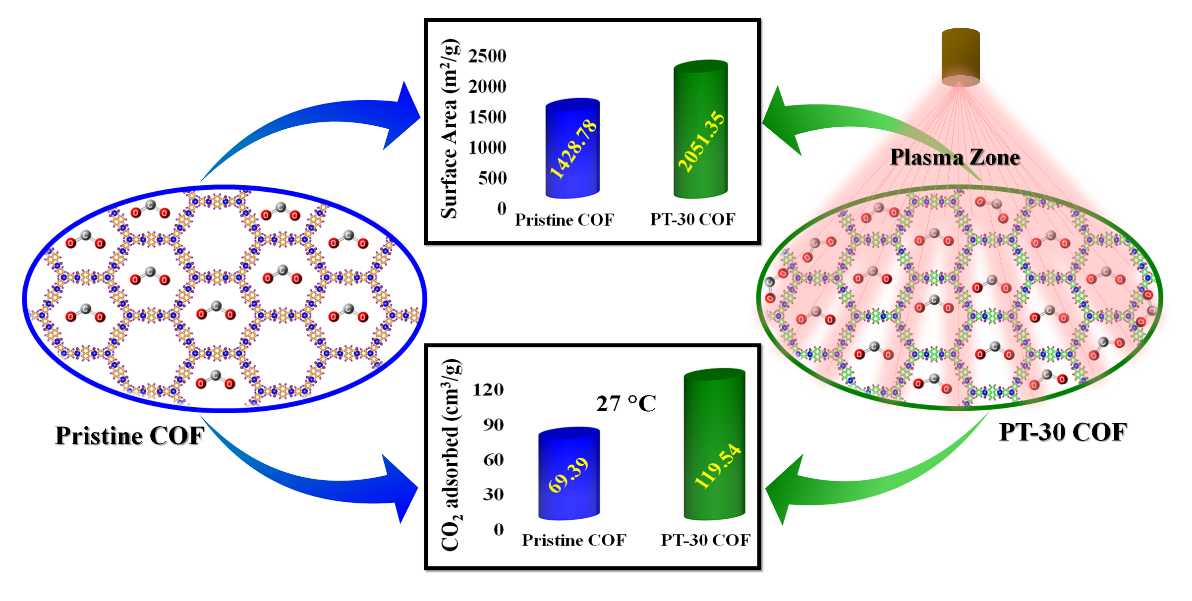

Dr. Anamika Kalita and her research group at IASST in conjunction with the Plasma laboratory also adopted a post-treatment methodology called Air Liquid Interfacial Plasma (ALIP), on a COF material---a class of materials that form two- or three-dimensional structures with strong covalent bonds through reactions between organic precursors, to increase surface adsorption properties and enhance carbon capture.

The Air Liquid Interfacial Plasma (ALIP) technique is a time-efficient, one-step cost-effective and green method. The set-up for ALIP technique includes easy accessories such as two electrodes comprising of a stainless steel (grounded electrode) and a Cu electrode. It generates reactive species which can interact with the adsorbent surface to refine the surface with new functionalities and boosts the CO2 adsorption capacity. This method helped fine-tune the surface properties and achieve an ultra-high surface area.

The ALIP protocol explored in this work has improved the surface area of the pristine COF by 43.57%. In addition, the post-furnishing ALIP treated COF has revealed an efficient uptake of CO2 at a wide temperature ranges from 7-37 ℃ and a pressure of 1 bar. Under ambient condition, the ALIP-treated COF improves by 72.27% over the untreated COF.

Publication Link: https://doi.org/10.1002/chem.202300756

For more details, contact Dr. Anamika Kalita: Cell-9706990846 and E-mail: anamik[dot]kalita01[at]gmail[dot]com

The research published in Chemistry-A European Journal under the reputed Wiley-VCH publishers sets a new paradigm to design as well as refine the properties of COF materials via a post-furnishing strategy to deal with the challenges of CO2 capture.